This week I read in Forbes that a new study (published in October 2015 issue of Anesthesiology) finds that medication errors occur in one-half (50%) of all surgeries. This incorporates the perioperative, surgery and postoperative periods. The data continues to support the cold reality that as healthcare providers, we must change to protect our patients.

This week I read in Forbes that a new study (published in October 2015 issue of Anesthesiology) finds that medication errors occur in one-half (50%) of all surgeries. This incorporates the perioperative, surgery and postoperative periods. The data continues to support the cold reality that as healthcare providers, we must change to protect our patients.

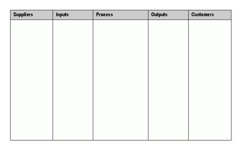

Creating processes that provide assurance that our outcomes will be predictable is where we begin to change this trend. The SIPOC diagram for process identification and control is a great tool. It is typically used in the “Define” stage of DMAIC in a Six Sigma project. SIPOC has been used for high-level identification of gaps between suppliers and process owners/operators and the process owner/operator and the customer. In our complex profession of healthcare, we too often fail to consider the effect of all suppliers and all of the needs of the customer(s).

Let’s quickly identify the components of SIPOC. It is Suppliers, Inputs, Process, Output, and Customer.

S- Suppliers: those that provide an input or inputs to the process. Some are direct and some are indirect.

I-Inputs: information, services or materials that are used in the process. These inputs likely a combination of these in complex processes

P-Process: the activity or activities that transforms inputs into outputs while adding value

O-Outputs: information, services or materials that are a result of the process and given to the customer

C-Customer: the recipient(s) of the process outputs. The customer can be internal or external.

A five (5) column SIPOC form is used to capture data from each of these functions. Determine the best method to capture the data to enter into the SIPOC form.

A five (5) column SIPOC form is used to capture data from each of these functions. Determine the best method to capture the data to enter into the SIPOC form.

Use a multi-disciplinary team to complete this process. This team must truly represent each function, department or service that affects or is affected by the process being analyzed. This step is foundational and absolutely necessary for the success of the SIPOC. Do not skimp on his step. Historically, when we fail to consider all perspectives, we experience surprises.

Working through each step in the SIPOC, the group will create a detailed description of all pertinent inputs and outputs necessary to ensure the process activities are consistent. Consistency is necessary in our complex healthcare processes. Consistent processes can be more sustainable with process re-engineering, thus creating a safer patient environment.

SIPOC is typically used as a means to gain a high level understanding of the process in a Six Sigma project. I propose that in healthcare, we consider using a SIPOC at all level of processes (macro, mezzo and/or micro), depending on criticality and complexity of the process. Consideration must also be given to the fact that there are multiple interactions among our processes, often times between the levels of processes. This adds to our complexity.

A firm understanding of our critical and complex processes, specifically their sequence and interaction with other processes, will help ensure that our efforts will produce consistent sustainable results. SIPOC is one tool that will help us with this process analysis. Others tools include Turtle Diagrams, Spaghetti Diagrams and Flowcharts. Find a tool that will help your organization to complete this activity effectively. Knowing how our processes are sequenced and interact with other processes will help eliminate surprises. The outcome will be a safer environment for patients, families and employees. This is why we go to work every day- to do no harm.

Bio:

Ted Schmidt is a Pharmacist, a Certified Enterprise Risk Manager (CERM©), and a Senior Advisor with BlueSynergy Associates, LLC. BlueSynergy Associates maximize innovation, experience and customer perspective to reduce risk and make hospitals a safer environment. He currently advises and instructs hospitals in quality, risk, safety and environmental management systems. Ted led the largest ISO 9001 implementation in healthcare at the Veterans Administration. He is a Senior Member of the American Society for Quality and a certified Lead Auditor in quality management systems by Exemplar Global. He can be reached by email at tschmidt@bluesynergyassociates.com. Follow BlueSynergy on LinkedIn and Twitter