High temperature & humidity is a common test condition. For specific failure mechanisms there are models available (or you can create a model) to determine the translation from test to use conditions.

High temperature & humidity is a common test condition. For specific failure mechanisms there are models available (or you can create a model) to determine the translation from test to use conditions.

These acceleration models generally only apply to one specific failure mechanisms and do not apply to a system level estimate of life. If the failure mechanism is the dominate failure mechanism for the product, then an ALT exploring just that mechanisms would provide a life estimate.

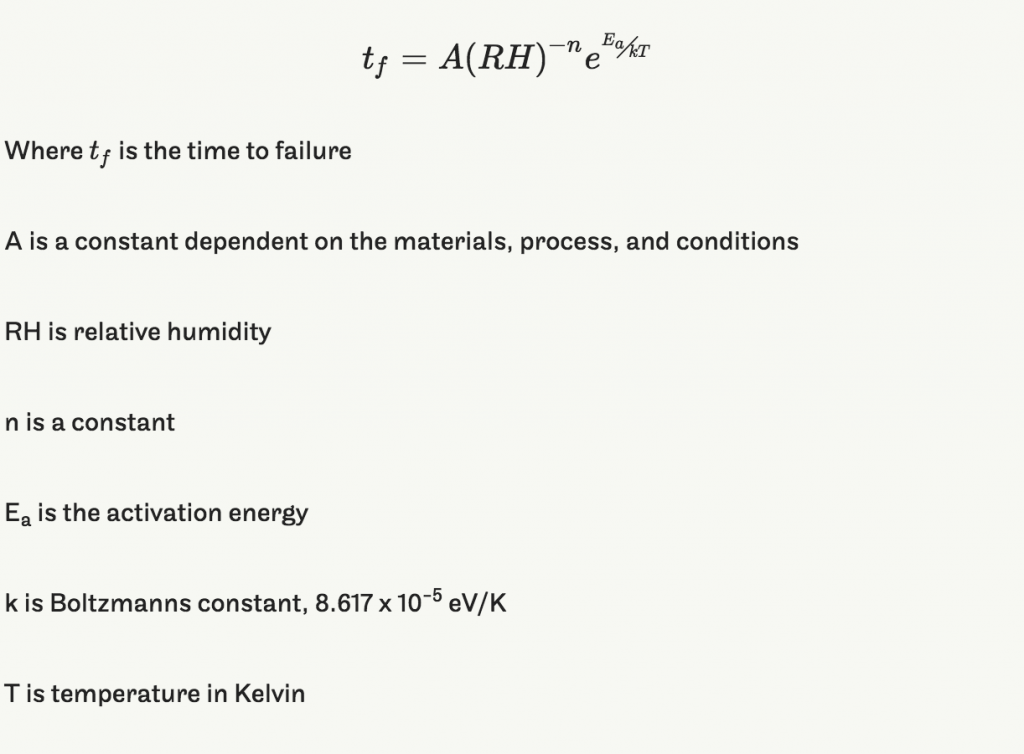

Peck’s relationship is an acceleration model for effect of humidity on the metallization elements of integrated circuits within plastic enclosures (typically an epoxy over molding).

Peck’s Relationship for Temperature & Humidity

When electronic components moved from small metal cans to epoxy packaging, one of the issues was moisture ingress leading to the silicon device failing quickly. If the epoxy over-molding did not form an adequate seal the application of a relatively high humidity at an elevated temperature could determine if the package would survive nominal temperature and humidity conditions for an extended time.

Peck and colleagues gathered reports and studies of the effects of temperature and humidity on the time to failure behavior for a range of epoxy based packages. The model they developed is empirically derived from a large number of different life studies.

Acceleration Factor or Model

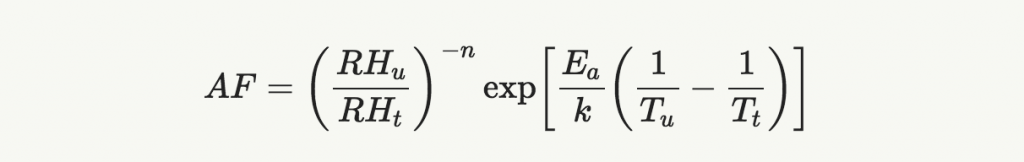

Using Peck’s relationship as a ratio of test conditions over use conditions we are able to eliminate the constant A, it simply cancels out.

The ratio results in the acceleration factor, AF, or the number times one can multiple the test, subscript t, determined time to failure data to estimate the use condition, subscript u, expected time to failure duration.

Note the model is a form of an Erying model being the product of the inverse power law for humidity and the Arrhenius equation for the temperature elements.

The Constants n and Ea

The constants were determined fitting the data from hundreds of studies using simple regression techniques. The constants vary depending on the:

- Geometry

- Material set

- Process conditions

- Testing conditions

- Use conditions

The values in Peck’s paper and in subsequent papers or books is only a starting point providing a rough model. You should determine the appropriate constants for your particular circumstance when ever possible.

In Peck’s paper he reports n = 2.7 and Ea = 0.79 eV. These values are also listed in Nelson’s discussion of the model.

Wayne Condra discusses Peck’s relationship and uses n = 3 and Ea = 0.9 eV.

Summary

You acceleration factor may differ. Peck’s relationship is a great place to start when evaluate the longevity of moisture induce IC failure with epoxy over molded components. You can improve your acceleration model by determining the fitted constants for your specific system.

Finally, keep in mind Peck’s relationship is an acceleration model for temperature & humidity evaluation of moisture induce IC failure within epoxy over-molded components. It is not a general model for any application of temperature & humidity testing.

Peck, D Stewart. “Comprehensive Model for Humidity Testing Correlation.” Reliability Physics Symposium, 1986. 24th Annual (1986): 44-50.

Nelson, Wayne. Accelerated Testing: Statistical Models, Test Plans, and Data Analysis. Edited by S S Wilks Samuel. Wiley Series in Probability and Mathematical Statistics. New York: John Wiley & Sons, 1990.

Condra, Lloyd W. Reliability Improvement with Design of Experiments. New York: Marcel Dekker, 2001.