W hen people discuss Supply Chain Management, there doesn’t seem to be any common understanding of what it is all about. I get it! To some, it is software and technology. To others, it is just purchasing and logistics. And still others believe that it is ‘big data’ and analytics. No wonder that eyes glaze-over when the subject is mentioned.

hen people discuss Supply Chain Management, there doesn’t seem to be any common understanding of what it is all about. I get it! To some, it is software and technology. To others, it is just purchasing and logistics. And still others believe that it is ‘big data’ and analytics. No wonder that eyes glaze-over when the subject is mentioned.

I’m not here to define SCM; you can find the definition on the Council of Supply Chain Management Professionals website. I want you to understand some of the concepts behind supply chain management.

I’m a Simple Guy

Which is why I’m attracted to the global enterprise supply chain. It has a beauty and elegance that are found in the simplicity of design, agility of movement, and purposefulness of execution. If you have observed the innermost workings of companies such as Dell, Walmart, or FedEx as I have, you will have experienced beauty as close to Michelangelo’s Sistine Chapel as one can imagine.

Because I’m a simple guy, I think that everyone should look at Supply Chain Management differently.

Because I’m a simple guy, I think that everyone should look at Supply Chain Management differently.

Think of It This Way

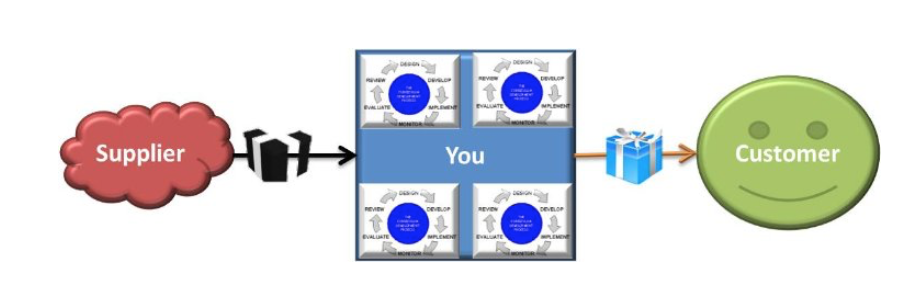

Forget about Supply Chain Management…think about a business, any business of any size. Let’s just say it is your business. In its simplest form, a business consists of three things: Suppliers, You, and Customers. It doesn’t matter what industry that you are in, all businesses have these three elements.

Businesses purchase products or materials from suppliers. They expose those materials to one or more processes within the company and then they provide the finished product to their customers. These are the essential relationships and activities that companies like Walmart, Publix, HP, and even my favorite restaurant (Two Dog Diner) go through every day.

Everything involving the relationships and activities between Suppliers, You, and Customers is SCM and that means that managing a Business is managing the Supply Chain. Let’s explore two critical aspects of managing a business and the supply chain: Strategy and Flows.

Strategy

Strategy

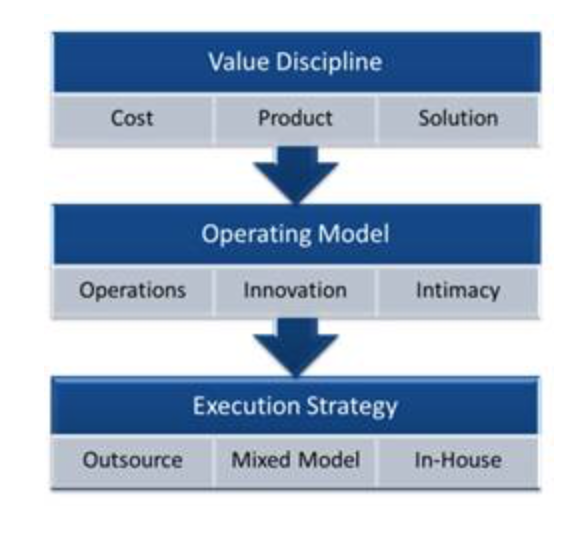

We must Plan the Business and then Plan the Supply Chain so that the relationships and activities between Suppliers, You, and Customers are complementary and supportive. In order to avoid a situation where the “tail wags the dog” it is important to jointly plan both the Business and the Supply Chain, always remembering that the Business needs will dictate the Supply Chain requirements.

Customers don’t buy products, they buy Value.

When you Plan the Business, you want to think about the Value Discipline by which your customer’s buy Value. There are three of them: Best Total Cost, Best Total Product, and Best Total Solution. Each Value Discipline aligns with a particular Operating Model of Operations Excellence, Product Innovation, or Customer Intimacy. We must select the operating model that best aligns with our customer’s Value Discipline and then remain at par with the market place for the other two. After we align these elements, we must determine the most appropriate Execution Strategy to deliver that value. Three common Execution Strategies are Outsourced, In-House, or a mixed model.

It pays dividends to get those Business elements correct because they will drive the Supply Chain design and execution…which means they drive Customer Satisfaction, Financial Performance, and Operational Effectiveness.

While we are planning the business, we should always be considering how the supply chain can best complement and support our business strategy. This requires constant communication with the business leader accountable for Supply Chain Management. Maintaining constant communication and solicitation of feedback will help to ensure that the task of Planning the Supply Chain will be most effective.

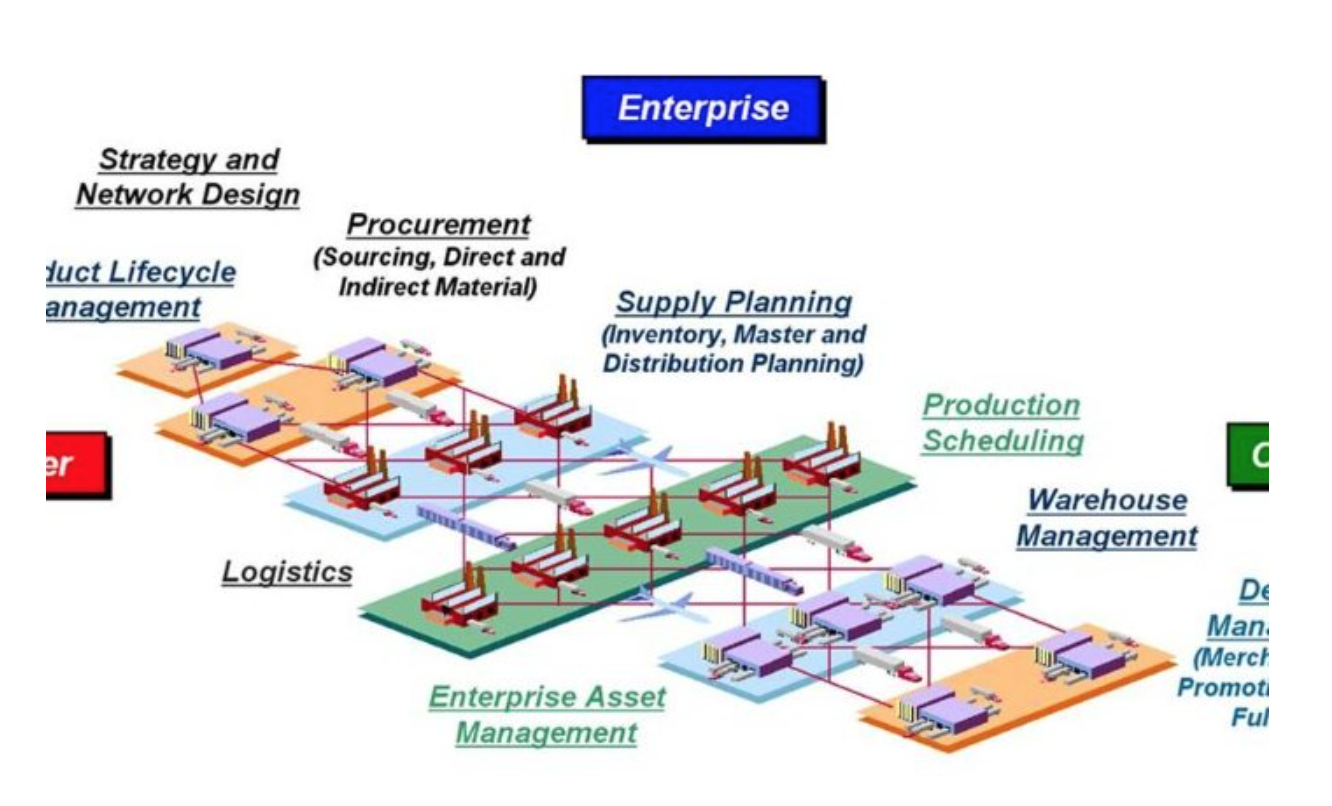

Once the business defines the customer and their Value Discipline, Operating Model, and Execution Strategy we must plan the major elements of the supply chain.

Plan the Channel.

This task is too important to be planned by only Sales & Marketing. It is best to be as flexible and growth oriented as possible. If you only plan for one sales channel, that decision could haunt you forever. I always recommend taking an omni-channel approach that can be scaled up or down depending on where the business wants to focus their initial efforts.

The Channel will drive the Plan for Sourcing, Conversion, and Delivery. Sourcing is where/how you obtain products or materials from Suppliers. Conversion is where/how you convert their materials into Finished Goods. Delivery is how you take your Finished Goods to your customers.

You may or may not have immediate requirements to Plan Services such as installation, commissioning, repairs, warranty work, or upgrades but if there is even the slightest possibility that you will in the future, it is best to plan for it now.

You will most likely have to Plan Returns for various reasons such as damage, order errors, and quality issues. Plan Recovery may not YET be a consideration but many sustainability programs encourage a methodology of environmentally friendly removal of end-of-life products from the marketplace and ultimate disposition by the manufacturer.

All of this and we haven’t talked about warehouses, logistics, or software. It is amazing how broad a net SCM really casts. Let’s talk about Flows.

Flows

Most of the above actions are based on three activities that I call Flows. A Flow is the progressive and deliberate movement of a determined number of things from one state-of-being or process to another.

Flow of Products. Think of this as the flow of water through a waterfall feature in a garden. Turn on the water (inventory) and it flows into a basin (company). The water collects in the basin (conversion) until it reaches capacity (Finished Goods). Then the water trickles out of the basin as a waterfall into an awaiting collection basin (customers).

As we increase the velocity of the water flow (inventory from supplier), less water is collected (conversion) in the basin (company) and it reaches the collection basin (customer) much faster. This is similar to how the supply chain responds to increased demand, except we rely on the customer initiating the increased flow rather than our suppliers driving it in this very simple example. As the velocity increases, less water is collected even though more total water is flowing through the waterfall.

Flow of Cash. In this example, once the customer receives the Finished Goods, Cash flows from the customer into the business. We collect, account for, and allocate all of the Cash into different “buckets.” Some of this Cash flows into a bucket that we call “profit.” Other portions flow into buckets we call “compensation,” “taxes,” and “equipment” among others. A portion also flows to suppliers as payment for the Products we received from them.

Many companies like to collect Cash as fast as possible and then take as long as possible to make payments. One company I know would charge customer credit cards (or so it was alleged) when they placed an order and then took several days to ship the product. This permitted them to collect interest on the customer’s Cash before they “spent” money on inventory. Another company notoriously waited +90 days to pay suppliers. It was alleged that they sat on a float of roughly $1 Billion every quarter.

Most financial folks will tell you that there is nothing wrong with leveraging the “float” in business. The problem is that suppliers aren’t stupid. Regardless of how long you take to pay them, suppliers will calculate their cost of capital and impute the cost into the goods they sell you. This means that you are actually paying suppliers for the length of time it takes you to pay them!

Flow of Information. Because Flows are progressive and deliberate, as well as determined in quantity and between one state or process and another, we require something more than willpower to drive the machine we call a business. The driver is Information.

One type of Information we need has to do with customers. We must know what our customers want and when they want it. This information comes from various sources and flows into our company for analysis and consideration as to the type of products our customers want, when they want it, and what they are willing to pay for it.

We use this information internally to determine what we need to make, how much we need to make, when to make it, and how fast we need to make it. It flows into our various internal operations and drives the conversion of supplier products into Finished Goods.

We finally use this information to manage the amount of products or materials we need to buy from our suppliers, when we need to receive it, and how we are going to stage it so that our internal operations can convert them into Finished Goods ready for our customers.

The End?

Not exactly!

If it were easy, everyone would be doing it. Development of Strategy and the Flows of Products, Information, and Cash are more complex than I’ve indicated in a supply chain of even modest levels of sophistication. There are numerous processes, procedures, and protocols that must be identified, assessed, and deployed for a business to be successful.

However, it is enough to get you thinking about Supply Chain Management from a different perspective.

- Think about your relationships with suppliers and customers and how these two ends of your supply chain are critically entwined.

- Think about your suppliers and how your flows of products, information, and cash can either adversely or positively impact their ability to meet your needs and those of your customers.

- Think about your internal operations and how they interface with your suppliers and customers at critical junctions within the business and how those junctions can adversely or positively impact your Strategy and Flows.

- Think about when, where, and how cash flows both in and out of your company, customers, and suppliers. Try to optimize those flows.

- Think about the information that you receive from your suppliers, customers, and internal operations and how that can be leveraged to benefit everyone.

- Think about the optimized and synchronized multi-directional flow of Products, Information, and Cash between your customers, your company, and your suppliers and how you can use it to drive sustainability and profitability.

- Think about making it simpler.

This is a very simple way to look at SCM. I will be the first to tell you that there is much more involved in Supply Chain Management than what I’ve described. But just because it might be complex, doesn’t mean it has to be complicated. After all, the beauty of Supply Chain Management is in its simplicity.

Bio:

Rick Feltenberger is a Principal at The Supply Chain Center and innovator behind RightFlow™, an integrated supply chain design that optimizes and synchronizes the flow of Products, Information, and Cash throughout the global enterprise supply chain.