Over the last few decades there have been drastic upheavals in the manufacturing industry as a whole. But now the alarming increase of counterfeiting has surfaced to threaten the global supply chain. Is the criminal underground solely to blame? Or has the manufacturing industry unknowingly but directly contributed to this growing gray business?

Over the last few decades there have been drastic upheavals in the manufacturing industry as a whole. But now the alarming increase of counterfeiting has surfaced to threaten the global supply chain. Is the criminal underground solely to blame? Or has the manufacturing industry unknowingly but directly contributed to this growing gray business?

This growth of counterfeiting can be attributed to the following forces:

- A slumping economy

- Low-cost advanced technology

- Trade globalization

- Consumer complicity

- Channel and market expansion

- Powerful global brands

- Weak international regulations and enforcement

The main cause of this growth is the digital age; the Internet has turned counterfeiting into a low risk market by allowing these groups an unlimited access to the global market, low cost communications and free access to information of proprietary or confidential nature. But most of all the Internet allows for anonymity.

The main cause of this growth is the digital age; the Internet has turned counterfeiting into a low risk market by allowing these groups an unlimited access to the global market, low cost communications and free access to information of proprietary or confidential nature. But most of all the Internet allows for anonymity.

Given the emergence of the above seven reasons, supply chain managers should not be surprised by the manifestation of counterfeiting. The efforts to protect intellectual property have been largely ineffective due to organizations all too eager to share their standard operating procedures, transfer tooling and share quality manufacturing training ideas. In order to diminish these risks manufacturers must objectively assess their existing efforts by considering the following:

- Conduct due diligence for facility security, inventory accountability and proper destruction of unsalable items?

- Consistently audit external facilities that operate within our supply chain?

- Ensure all retired but tangible assets are properly destroyed?

- Do existing processes and procedures allow trusting the verification?

Companies that are unwilling or unable to meet these criteria will remain vulnerable to and enable the counterfeiters to continue their ‘gray market’ production.

Today there is a large cache of tools, practices and countermeasures available for use by manufacturers, especially for those firms operating in such places like China, Brazil, India and Paraguay. However, the industry as a whole will continue to struggle against counterfeiters until it correctly weighs the knowledge and unique outlook of supply chain counterparts.

(Asian countries, in particular China, are responsible for the vast majority of counterfeit electronics reaching the U.S.)

(Asian countries, in particular China, are responsible for the vast majority of counterfeit electronics reaching the U.S.)

The lack of a single entity or legislation to provide complete supply chain line protection has led many companies towards technology experts to assist in brand protection. In return manufacturers are allowing these technical experts inside knowledge to their best practices to integrate authentication solutions. Clearly, we can see the dangers in continuing this activity.

Technological experts can and often do present a case for adopting ACF (anti-counterfeit) technologies. There is still resistance to this as many supply chain directors claim that visibility is detrimental to their success. Suppliers, vendors and distributors as well are reluctant to collaborate. This fear has been long doormat: a belief that sharing will diminish their value to the manufacturer and lose business. Manufacturers who hesitate in fighting counterfeiting can adhere to these principles:

- Welcome the threat. Campaign for the implementation of a zero-tolerance policy for violations by employees and or suppliers.

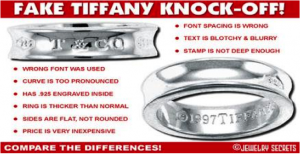

- Protect Intellectual property by increasing control of production materials throughout the entire supply chain ( as picture below illustrates)

There are a number of available anti-counterfeit technologies available for companies. Of course, even with these technologies due diligence for the best product for your company must be performed. The due diligence should be based upon projected risk of the brand profile, active trade channels and target markets. These options must be capable of full integration with company’s operations, upstream and downstream – sensory authentication, digital authentication and track and trace systems. For those not familiar with these options perhaps a short summary of them will help:

- Sensory authentication – overt and semi-overt packaging markings such as color changing inks or holograms.

- Digital authentication – forensic markings, barcodes that authenticate by package or product scan.

- Track & Trace system – custom built scanners that use unique identifiers to track product movement or retrace the chain of ownership through the supply chain.

As with any solution these have their own strengths and weaknesses. Sensory authentication can be vulnerable to duplication by counterfeiters. Digital authentication adds a layer of security but must be used in conjunction with a corresponding device. Track & trace solutions require the largest investment as it has a multi-layer approach to security of product. This solution is mostly used by pharmaceutical companies.

(Securing the Pharmaceutical Supply Chain)

(Securing the Pharmaceutical Supply Chain)

Even before we bring in the technology experts perhaps a consultation with a brand expert is in order. These specialists can provide objective risk appraisal and advice on proper equipment and project delays such as unforeseen costs.

As counterfeiting continues to grow as a ‘gray market’ supply chain leaders must invest in brand protection such as auditing SOP’s to revising distribution practices and implementing ACF solutions.

Remember, no single company, technology practice or program can or will lessen this risk to the supply chain. Only cooperation and collaboration from all – manufacturers, suppliers, vendors, distributors and legislators – will present a workable solution.

Bio:

Expertise in lean six sigma manufacturing systems, inventory systems and process improvements functions. Accomplished in use of optimization models to determine least cost facilities and drill down to workflow details in support of process and profit management. Oversaw all Inventory Collaborate effectively with business managers to resolve variances, refine forecasts and identify opportunities for improvement. While at Reckitt Benckiser, Linde Gas and Johnson & Johnson wore several hats including inventory manager, implementer and trainer of benchmarking and dashboard analytics, leader of cost optimization projects such as Lean and Lean Six Sigma, created and implemented cost and inventory metrics, collaborated across functional silos such as production, receiving, plant personnel and shipping to ensure inventory and cost systems integrity, wrote and implemented and trained staff on new Procedures to align with projects and continuous improvement leader.

Member of various accounting and operational trade associations such as; The Council of Supply Chain Management Professionals, The International Supply Chain Education Alliance and The Society of Cost Management. My interests outside of my work are mostly outdoor activities like hiking, camping, tennis, etc., with a slight lean to gourmet cooking.