Today, employee wellness and safety remain a top priority for corporations, and having a first-in-class safety management system put in place is not just a nice-to-have, it’s essential. As digital capabilities continue to evolve, modernizing ineffective, slow, and expensive processes with renewed tools is one way to invest in industrial & occupational safety professionals and improve workplace health and safety.

Today, employee wellness and safety remain a top priority for corporations, and having a first-in-class safety management system put in place is not just a nice-to-have, it’s essential. As digital capabilities continue to evolve, modernizing ineffective, slow, and expensive processes with renewed tools is one way to invest in industrial & occupational safety professionals and improve workplace health and safety.

Below, I shall identify various avenues to advance safety procedures with the latest digital tools — from administrative to the jobsite — to further ensure a better-connected workplace.

Upgrade your health & safety administrative programs.

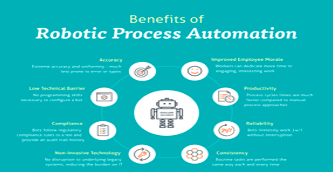

From compliance to risk assessment and mitigation, employee health & safety programs focus on a variety of factors. Too often administrative components associated with these programs are repetitive, require manual entry and are prone to many inaccuracies. In a modernized digital world, these processes are outdated and unproductive for achieving forward-thinking, quick assessments to support the health and safety for employees.

However, the good news is that these administrative responsibilities can be streamlined through digital tools, providing organizations with fast and accurate data to improve health & safety prevention. For example, consider investing in software to assist you with OSHA record keeping. Software exists to log incidents, set corrective actions and due dates. These solutions enable full transparency into incidents and hold workers accountable for training.

Additionally, companies are utilizing digital management solutions for PPE programs to enhance employee health and safety while efficiently handling tasks. With these digital management tools, you can seek out a PPE partner to not only lead you through the outfitting process, but also help you identify your organization’s needs and guide you through building tailored programs to ensure PPE is suitable for your jobsites.

Companies are utilizing digital management solutions for PPE programs to enhance employee health and safety while efficiently handling tasks.

Before selecting a PPE partner to enhance your digital capabilities, there are important factors that should not be overlooked, including:

The latest data: In order to speed up processes, partners should offer real-time data around health and safety compliance and employee eligibility, such as digital records of purchases made by employees.

Streamlined processes: An efficient management tool saves time for administrators without making tasks more complicated or challenging. If you can simplify the process of outfitting employees through a digital program, this can remove the step of manual verification and therefore save the company inventory carrying costs.

Customization: An essential feature to allow for optimal flexibility for your organization, along with being able to facilitate product selection to guarantee compliant items are used. Digital portals for organizing, choosing, and customizing health & safety gear lead to advancing safety.

Availability and convenience: A provider should be accessible and be ready to complete orders for all your employees regardless of where they are. For instance, organizations are offering online vouchers for employees to easily redeem PPE. A partner should have a variety of locations – including mobile stores, and online ordering – warranting that PPE gear and services are always available.

Advance to augmented reality training sites

Another digital phenomenon that continues to increase in popularity is augmented reality (AR), specifically for jobsite training purposes. AR can replace traditional methods and interconnect a virtual reality with real-life visuals — easily replicating training scenarios and processes in less time while saving on expenses.

For example, overlaying digital content onto real jobsites enables employees to intermingle with environments and gives contextual details about their workspace via smartphones or AR headsets. This creates an interactive experience and allows employees to learn safety procedures for potential situations — excluding the danger factor that would be present with on-the-job training. It also provides a more engaging experience for employees to get comfortable with processes versus just reading text-heavy manuals.

Technology as a uniform

Across many industries, wearing technology is on the rise — providing a variety of new safety measures. From glasses with heads-up displays and 5G-connected hardhats, to PPE with embedded sensors that monitor health stats such as heart rate or jobsite data like environmental hazards,

PPE has become more digitized and innovative, and you can now work harder and provide more for your employees.

Wearable technology gives both health & safety professionals and employees a wide-ranging look into the potentially serious injury and fatality situations on a jobsite. These digital devices can modernize on-site job monitoring, provide proactive risk management, and increase productivity for both you and your employees. Data from wearable technology can be saved and analyzed to support future efforts for improvement across safety processes and inform you of unforeseeable issues.

Keeping health & safety at the forefront as automation increases and labor shortages continue, manufacturing is a long-standing staple of our economy. In the U.S., it contributes 10.7% of total output, and in Canada, it accounts for 10% of the gross domestic product (GDP).1,2 The three largest manufacturing categories in the United States and Canada are computer and electronic products, chemical manufacturing, and food and beverage.3 Electronic manufacturing in the U.S. has grown 162% from 2006 to 2021, while auto manufacturing has grown approximately 31% over the same time period. More growth is expected in the future with the accelerating adoption of electric vehicles (EVs).

The past decade has seen a massive change in the manufacturing industry, brought on by the increased use of automation, the pandemic’s impact, and an ongoing labor shortage. So, what have been the biggest changes? And how will the industry continue to adjust and innovate to meet new demands, while continuing to prioritize safety? The following changes are some of the most notable in shaping the industry both today and in the years to come:

Increased adoption of automation and robotics

Robotics in manufacturing often takes on highly repetitive jobs or tasks that are less appealing for human labor because they are higher risk, such as roles involving heavy lifting. Today’s robotic technologies incorporate advanced sensors, artificial intelligence (AI), and other capabilities that allow them to perform precise tasks with high levels of efficiency, helping to increase overall productivity for manufacturers.

According to the International Federation of Robotics (IFR), total installations of robotics in manufacturing in the U.S., Canada, and Mexico grew by 12% in 2022 to reach more than 41,600 units. The automotive manufacturing sector is the largest adopter of these technologies, installing 30% more robots in 2022 than they did in 2021.5.

Greater connectivity and intelligence

The terms “smart factory,” “industrial internet of things” (IIoT), and “Industry 4.0” have entered the manufacturing discourse, referring to how devices and machines are now increasingly interconnected so they can share information and communicate with each other. Through these advances in technology, the shop floor can be directly connected with decision makers, and production data can be collected and analyzed in real time, enabling timely operational improvements and better-informed decision.

As an example, gathering and analyzing data on equipment health over time enables predictive maintenance; rather than waiting for a machine to break down, requiring a last-minute scramble to find a repair technician and costly downtime, machinery can be maintained at optimal times throughout the year to increase the technology’s overall uptime.

Nearly 60% of manufacturers in a recent survey indicated they are creating or expanding internal training programs for employees to help mitigate the skills shortage in the future.

Shifting labor demands

The National Association of Manufacturers (NAM) reports there are currently 13 million people employed by more than 240,000 manufacturers throughout the U.S., with an additional 4 million manufacturing positions expected by 2030.7 However, the nature of manufacturing work is shifting. As humans and machines are increasingly working together, new types of jobs like Manufacturing Cybersecurity Strategists, Digital Twin Architects, Robotics Technicians, Predictive Supply Network Analysts, or Smart Factory Managers will be required.

This shift has led to a skills shortage, where many manufacturing companies are struggling to find labor with enough experience or the right skillsets to meet today’s demands. As a result, nearly 60% of manufacturers in a recent NAM survey indicated they are creating or expanding internal training programs for employees to help mitigate the skills shortage in the future.

The pivotal role of safety

As these changes continue to evolve the manufacturing sector, safety for workers and facilities is just as important as ever. With humans and machines working alongside each other, there are several factors to consider:

Noise: With robots and automation technologies taking on many manufacturing roles — from welding, painting, lifting, and forging to stamping, forming, machining, palletizing, and assembling — the noise level in many factory

environments is going up. Wearing appropriate hearing protection, such as ear plugs or passive earmuffs, is critical to safeguard workers’ hearing over the long term. Nearly half of all manufacturing workers have been exposed to hazardous noise levels, and 28% who are exposed to this noise report not wearing hearing protection.

Vision: It is important to keep a clear line of sight when in a factory setting where humans and various powerful machines are operating simultaneously to avoid collisions or other injuries. Protective, anti-fog eyewear can both safeguard workers’ eyes from flying objects and help keep their vision clear when they are sweating or moving into different temperature environments within a building. In addition, blue light-blocking glasses can help protect the eyes from glare and potentially reduce retinal damage from exposure to blue light.

Electrical safety: As the world moves toward greater electrification, new considerations enter the picture for worker safety. For example, manufacturers of lithium-ion batteries and electric vehicles need to equip their employees with electrical safety gear like insulating rubber gloves and dielectric boots to help safeguard them from electric shock, arc flash, and burns they may encounter at different stages of the EV manufacturing process.

Hand protection: Hand coverings remain the largest personal protective equipment (PPE) product segment in north America., fueled by growth across manufacturing, construction, and healthcare in recent years.

Glove sales nationwide are expected to climb 11% through 2024.11 In auto manufacturing, gloves that provide enhanced dexterity and good grip are vital for workers handling small parts like nuts, bolts, and screws and workers attaching cables and wires. In the food and beverage sector, nitrile gloves offering chemical protection, cut resistance, and strong grip in both wet and dry settings is key. The proper gloves help manufacturing workers to do their jobs both effectively and safely.

In addition to head-to-toe protection for employees, the manufacturing industry has always prioritized — and will continue to focus on — safety for visitors to its factories. Whether it’s a technician coming into the facility to make repairs to a machine, a trainer coming in to teach a safety program, a salesperson walking the plant floor, or a logistics worker coming to pick up product, manufacturing operations must ensure each person coming through the doors is safe for the duration of their visit.

Furthermore, with many long-tenured workers in manufacturing now retiring and a new generation entering a changing manufacturing workforce,

training on both safety and new skillsets will be a key component for manufacturing operations across North America. The recent EY “Work Reimagined” study found that 60% of advanced manufacturing business leaders believe investing in and upskilling the workforce for evolving technology and work requirements is vital for a sustainable future of work.

Though manufacturing is changing and will continue to do so, safety will remain at the forefront for this industry to continue to innovate and produce the products we all depend on.

Bio:

Dr. Bill Pomfret of Safety Projects International Inc who has a training platform, said, “It’s important to clarify that deskless workers aren’t after any old training. Summoning teams to a white-walled room to digest endless slides no longer cuts it. Mobile learning is quickly becoming the most accessible way to get training out to those in the field or working remotely. For training to be a successful retention and recruitment tool, it needs to be an experience learner will enjoy and be in sync with today’s digital habits.”