The purpose of this article is twofold: 1. Present the question of how will RFID change the supply chain landscape and then 1. Highlight areas of this technology which may be critical to further development and implementation. In addition, I plan to show the differences between barcode technologies and RFID in their use for supply chain.

The purpose of this article is twofold: 1. Present the question of how will RFID change the supply chain landscape and then 1. Highlight areas of this technology which may be critical to further development and implementation. In addition, I plan to show the differences between barcode technologies and RFID in their use for supply chain.

WHAT IS RFID?

First a little background of RFID. Please pardon me if some of this is too detailed or seems boring. I am merely trying to set the stage for the present situation. The first such system was developed by the British in World War II to identify friendly or unfriendly aircraft. Each plane had installed a transmitter which received signals from ground stations. Needless to say this was a primitive RFID system and not very secure or reliable. The next important milestone occurred in 1973 when Mario Cardullo was granted a patent on RFID. This first widespread RFID could only detect whether the tag was present or not.

About the same time the Los Alamos National Laboratory in New Mexico supported research of this technology. This laboratory’s early claim to fame was the development of automated toll payment systems which is still being used today (today we know it as ‘Easy-Pass’). The next step in the process did not happen until 1999 with a joint venture of Los Alamos, Uniform Code Council, Massachusetts Institute of Technology and Gillette Corporation founding an Auto-ID Center. The primary result of this collaboration was the electronic product code (EPC).

In 2005 at Johns Hopkins University research and development students created the Point of Sale system by ‘cracking’ the code of electronic payments. With this breakthrough companies could monitor power levels in the RFID tag and levels of risks in specific areas. However, a controversy arose as to individual privacy because RFID tags could be read from great distances without person’s knowledge. The more sophisticated protections the more opportunities for potential failures or breakdown in security.

COMPARISON BETWEEN RFID AND BARCODE TECHNOLOGIES

In supply chains, the biggest advantage RFID has over barcodes is the capability to automatically read large groups of tags at one time. This eliminates the labor or manpower required to scan large volumes involved in the supply chain lines. Visibility in the supply chain systems allows for improvement in supply chain management in areas such as bottlenecks, targeted recalls and market research. Potential advantages for RFID systems reside in the reduction of fraud and counterfeiting, labor cost reduction, stock shrinkage reduction, improvements in warehouse stocking and customer satisfaction. The drawback to barcodes is sensitivity to atmospheric conditions and the possible interferences such as dirt, dust or foreign objects obstructing the scanner. However, there is no common solution for RFID implementations. Must fit RFID systems to company’s requirements; if company really needs RFID to reach 100% accuracy and reliability. The security of RFID in the supply chain can be observed from several different vantage points: health industry (radiation devices), vehicle access control, inventory location tracking, software and hardware protection and tracking origins of goods.

Development of privacy enhancing technologies is vital to future RFID research and acceptance by the public. In the future RFID will allow consumers to scan tags attached to a particular product to verify that the product is genuine. It will be used to track soldiers in battle, sense levels of glucose in diabetics and enable reading of bank accounts. In fact, the European Union is considering RFID tags in the Euro currency.

The RFID technology is here to stay. With new research and inventions for RFID new uses and fields of use will be adapted. Barcode will be a thing of the past but due to unpredictable corporate environment there is no definitive horizon for the complete replacement. Questions about reliability, security and privacy issues of RFID technology are very important so there remains the question of complete acceptance. Despite these controversies, there will be continued development and research of this technology with the goal of revealing all potential pitfalls for supply chain management.

Table 1. Levels of RFID in supply chain application

Level Use Application

| Item | Consumer units | Products and individual items |

| Case or Carton | Traded units | Boxes (packaging) product carriers |

| Pallet | Distribution units | Pallets / Trucks |

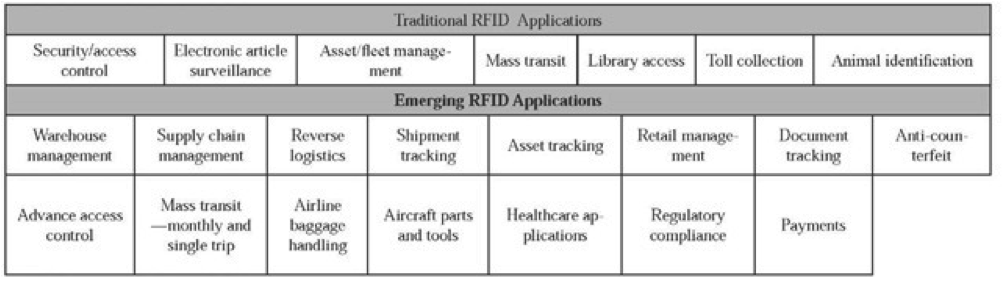

Table 2. RFID applicationa

Bio:

Expertise in lean six sigma manufacturing systems, inventory systems and process improvements functions. Accomplished in use of optimization models to determine least cost facilities and drill down to workflow details in support of process and profit management. Oversaw all Inventory Collaborate effectively with business managers to resolve variances, refine forecasts and identify opportunities for improvement. While at Reckitt Benckiser, Linde Gas and Johnson & Johnson wore several hats including inventory manager, implementer and trainer of benchmarking and dashboard analytics, leader of cost optimization projects such as Lean and Lean Six Sigma, created and implemented cost and inventory metrics, collaborated across functional silos such as production, receiving, plant personnel and shipping to ensure inventory and cost systems integrity, wrote and implemented and trained staff on new Procedures to align with projects and continuous improvement leader.

Member of various accounting and operational trade associations such as; The Council of Supply Chain Management Professionals, The International Supply Chain Education Alliance and The Society of Cost Management. My interests outside of my work are mostly outdoor activities like hiking, camping, tennis, etc., with a slight lean to gourmet cooking.