It’s apparent in today’s marketplace that far too many corporate management teams and manufacturing corporations are primarily focused on increasing sales, then profits, and lastly, if at all, assuring their products are safe and reliable. And to further compound that problem, making the assumption their employees know what to do with regards to preventing product recalls and product liability lawsuits.

It’s apparent in today’s marketplace that far too many corporate management teams and manufacturing corporations are primarily focused on increasing sales, then profits, and lastly, if at all, assuring their products are safe and reliable. And to further compound that problem, making the assumption their employees know what to do with regards to preventing product recalls and product liability lawsuits.

This area tends to be classified as “common sense”, with little to no need for training. As a result we’re faced with ever growing trends in product recall statistics, record breaking product liability lawsuit numbers, and bankruptcies.

It really doesn’t matter if you’re a $20M company or $20B, whether you manufacture consumer products, automotive, medical, industrial or commercial, or whether you have a Legal department or don’t, corporations are missing the mark across the board and will continue the current trends until the companies pursue training, from the top down. CEOs and Corp VPs are making mistakes just like the rest of the team, with countless news stories that support the claim.

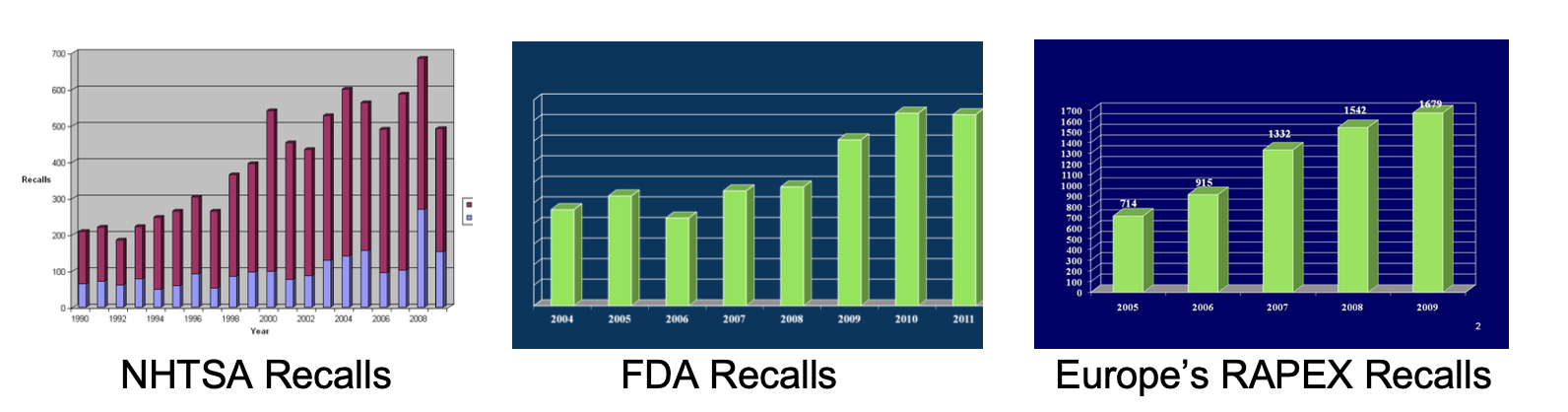

Product recalls are at record numbers, and have been growing every year for the past 10-15 years. Whether automotive products (NHTSA), medical device (FDA), consumer products which we hear about every day, or even recalls throughout Europe (RAPEX), the problems are getting worse instead of better and manufacturers of all kinds of products are recalling thousands or millions of their products.

In my analysis, studying product recalls as they are being announced, one of the largest causes of these recalls is due to “Design Defects”. The product designs were defective From my analysis the largest cause of these recalls and lawsuits is “Defects in Design” as opposed to “Manufacturing Defects”. The products were defective right from the start, and the Design Review Team didn’t catch it, if there really was a Design Review Team or Product Safety Team.

Here are all the primary focus areas that I recognize need improvement:

The Design Review Process – Don’t race your product to the marketplace before a thorough analysis takes place by trained employees, not just the Design Engineer.

Every company I work with initially says they regularly hold Design Reviews on new product designs, but they commonly say this out of ignorance because they don’t fully understand what a thorough Design Review looks like. The growing statistics speak for themselves. If manufacturers were doing a good job in their new product development efforts, the statistics would have been reversing themselves decades ago. What the management team fails to understand, are how Design Reviews really need to be handled. Until the CEO recognizes this and takes the time to get everyone trained and on the same sheet of music regarding the procedures for Design Reviews and Product Safety Reviews (please note there is a difference), manufacturing corporations will continue the Recall and Product Liability Lawsuit trends just as they have and will only learn a specific lesson from each major incident that surfaces, that is, if they survive.

Customer Service & Sales need to learn the difference between common product failures versus the “flags” of future catastrophic potential.

Usually before any catastrophic event ever happens, the question will be whether the company is paying adequate attention to the early warning signs or “flags”. Such early reports will normally begin to filter in through the Customer Service department, Account Management, Sales, Distribution, Tech Support or Warranty Returns, and the question will be whether anyone is paying attention and if this information is getting back to the right individual(s). All of your customer contacts need to learn how to decipher everyday potential product problems and failures, from ones that could lead to future serious safety/liability implications. This requires training and procedures.

Sales & Marketing needs to understand how pushing the envelope on safety & reliability can increase their liability.

For many Sales & Marketing departments, “pushing the envelope” or slightly exaggerating the quality or performance of a product is just part of the business, and they fail to see any legal issues from their efforts to make the sale. In most cases they have little if any knowledge of “Implied” or “Express” Warranties, and situations can go well beyond even that and enter into marketing fraud.

Legal & Purchasing departments must understand their “Terms & Conditions” won’t protect them when it comes to overseas suppliers.

Off-shore suppliers can’t be dragged into a U.S. courtroom, unless they maintain a U.S. presence, regardless of the fact that your P.O. terms and conditions contained an “Indemnification” clause. In addition there are other requirements your company needs to consider, such as requiring that all key suppliers anywhere in the world carry a certain level of product liability insurance through an international carrier, and naming your company as an “also insured” on their policy.

The entire management team needs to receive training on how to avoid “Dangerous Documents”.

The first piece of advice in this huge area of liability is “Quit sending so many emails or text messages”. Documents that surface in Discovery in every type of legal action, even Congressional investigations, tend to hang defendants. And this isn’t a middle-management problem, it involves CEOs, as well as Product Engineers, Quality professionals, Corporate VPs, Test Engineers, Sales, Account Management, Customer Service and numerous others. We all tend to note things we shouldn’t, and we feel confident no one on the outside will ever see it. And such quick messages allows us to quickly give our two cents or get something off our chest. Management teams are going to periodically face serious concerns and will have to make some corporate decisions, but they need to learn to handle delicate concerns. Just hitting “Delete” on your keypad will not end any concerns of it ever being found. They need to understand why this isn’t true.

Lastly, manufacturing corporations need to understand that certified Quality programs or performing FMEAs, or complying with Regulatory, will not change the current direction of the ever growing number of recalls and product liability lawsuits. It takes specific training in this field to understand where we continue to miss the mark in manufacturing.

About the writer, Randall Goodden is the author of the best selling books dealing with product safety and product liability prevention, the latest titled “Lawsuit! Reducing the Risk of Product Liability for Manufacturers” and the leading educator to manufacturing management teams worldwide on the topic. You can read more about the author at http://RandallGoodden.com

You can find my Bio at –

http://rlgoodden.tripod.com/Bio_Randall_Goodden_Website.pdf

there’s also a link to it on my website (address below).

Besides the event information on my website, here’s a couple of promos and links to my upcoming seminars –