Priority # 1 Professional Cleaning in Workplaces.

Priority # 1 Professional Cleaning in Workplaces.

At no time is cleanliness more critical than in a pandemic, the need for sterilization The founder of Safety Projects International Inc, has a mission – to help clean up Canada and several other countries. However, rather than doing it himself, Dr Bill Pomfret aka Dr. Clean is getting the workers themselves to do it – which is simple in its logic but offers a huge challenge in execution.

“The state of cleanliness affects us in every aspect of our lives, whether we’re a patient in a hospital, a pupil in school, a customer in a restaurant or an employee in the workplace,”.

“But most people fail to realize that cleaning is a science.” Treatment of the cause, not the symptoms, coupled with a healthy dose of preventive medicine, is his prescription for the endemic problem faced by most countries he visits. First, that means completely breaking down the tolerance for filth and replacing it with a culture of cleanliness.

And second, people will have to be educated on the best ways to clean up and to stay clean. Dr Pomfret is aware of the big, big job that is cut out for him, and that it involves more than just trying to change people’s attitude or mindset. That is but a starting point, even though it is a massive challenge in itself, as evidenced by the limited success of the numerous public cleanliness campaigns undertaken in many countries so far, including South Africa, the Philippines and Malaysia to name a few.

There is no question that 75-year-old Dr. Pomfret is committed to his cause. He has, after all, got a 50-year-old lucrative business. But to him, raising most country’s standards of cleanliness is part and parcel of occupational health and safety, both curative and preventive. Twenty years ago, he set up the education training Center for Cleaning Science and Technology in the Philippines (CCST), the country’s first such facility.

Located in San Isidro, Nueva Ecija the center conducts, inter alia training programs for the cleaning service industry, as well as local councils, building owners, and property managers. With the primary objective of raising the status and standards of the Philippines’s cleaning industry, After all, the number one export from the Philippines, is its people, mostly exported as caregivers.

The Open University’s Institute of Professional Development accredits the center’s cleaning proficiency program. Before setting up the facility, Dr Pomfret had personally audited and surveyed the way cleaning operators normally worked. Some of his findings proved to be shocking. For example, a same mop was used to clean the toilet and the kitchen; the same rag to clean the bathroom and to wipe tables in eateries; and a same pail of filthy water used to mop corridor after corridor.

His conclusion was that many professional and contract cleaners, not restricted to the Philippines, but Internationally were simply clueless about cleaning. Mostly, the exercise seemed to be aimed not at cleaning but at creating the impression that cleaning had been done, that is, not to sanitize but to look clean.

Cleaning workers have a difficult and often stressful job. Many are under pressure to clean more space in less time and with fewer workers. Shift work and isolation can also contribute to job-related stress and exhaustion. Partly as a result of this pressure, cleaning workers tend to suffer more workplace injuries than other groups of workers.

Ergonomic hazards are part of the problem. Lifting heavy objects like trash cans and repetitive motions like vacuuming can lead to injury, especially when workers are under pressure to work quickly. But the chemicals in cleaning products used by janitorial workers can also pose a serious hazard. Research on workplace injuries backs this up: in additional to musculoskeletal problems, respiratory and skin diseases are among the most common work-related health problems suffered by cleaners. These include asthma, eczema, and dermatitis. For example, A McGill University Work-Related Asthma Prevention Program found that nearly 10% of work-related asthma cases were caused by exposure to cleaning products.

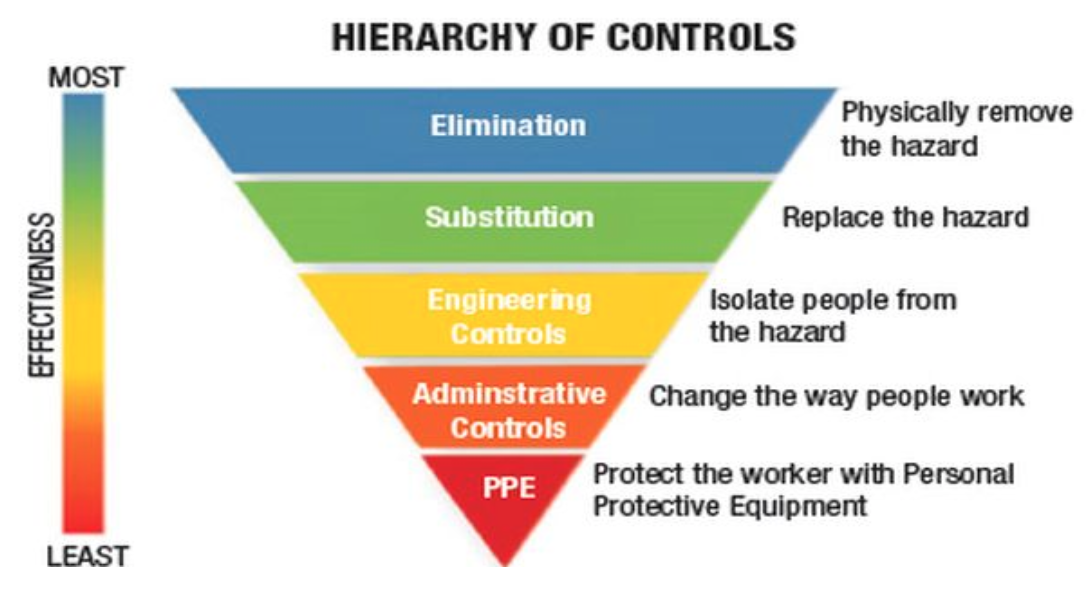

This issue affects not only janitorial workers, but also others working in an environment where cleaning products are used.so what can workplaces do to prevent these issues? The Safety Projects International Inc. hierarchy of controls to mitigate safety hazards identifies elimination of the hazard or substitution with a less hazardous alternative as the best way to deal with a health or safety hazard.

Only if elimination or substitution are not viable options should the workplace turn to engineering controls, administrative controls, or personal protective equipment to protect workers from workplace hazards.

In the case of janitorial workers using cleaning products, the hierarchy of controls suggests that elimination of unnecessary products and substitution of safer products is the most effective way to protect workers from chemical hazards.

However, it’s important to consider the workplace environment, rather than making changes to product selection in a vacuum. Workers not only want safe products they also want effective products that will enable them to do their jobs efficiently. Products that don’t work well can actually place additional pressure on janitors as they struggle to complete their jobs during the allotted time, leading to frustration and potentially increasing the risk of injury or ill-health. Fortunately, thanks to improvements in formulation, many products on the market today are both safer for workers and perform more effectively.

Third party certification programs can help identify institutional cleaning products that meet this high bar. For example, EPA’s Safer Choice program has certified over 2,000 safer products in a wide range of categories for both home and institutional use. All ingredients in these products must meet the program’s criteria for several human and environmental health endpoints. In addition, all certified products must meet performance standards. Using a reputable third-party certification like Safer Choice to select safer products helps protect against false environmental and health claims, as well as products that might use safer ingredients but just won’t work effectively.

Communication and transparency are important to ensure that workers know how to handle products safely. While the law requires disclosure of chemical hazards to workers via Safety Data Sheets, these don’t typically list all ingredients in the product. In some cases, information may need to be provided in a language other than English to ensure worker understanding.

New ingredient disclosure requirements for cleaning products have come into effect will give workers more information about what’s in the products they use. Training is also important to ensure that workers know how to use the products safely and effectively – for example, not mixing products that could result in a hazardous reaction and using protective equipment such as gloves or eye protection where appropriate. A comprehensive training program can also help protect janitorial workers from other workplace hazards, including ergonomic hazards.

Engagement between employers and workers can also help to ensure that janitors understand the reasons for green initiatives, including the use of green cleaning products, and have the support they need to implement them safely and effectively. While safer cleaning products are an important way to reduce chemical hazards to cleaning workers, they should be one part of a comprehensive program that ensures safe and healthy working conditions while treating workers with respect.

“The thing is you have to clean right,” Pomfret stresses. “You may not be able to control the public entirely, but you can control the cleaners and the quality of cleaning.” During his travels, Dr. Bill had also visited Singapore’s Institute of Cleaning Sciences, a franchise of the British Institute of Cleaning Sciences. Graduates, and professional cleaners are required to sit a proficiency test, both theory and practical.

In most countries, it is important that building owners, property managers and local councils send their staff for training, Dr Pomfret adds. This is because there are today very wide ranges of cleaning machines designed for all kinds of functions. Then there are the chemicals, which must be handled properly. In addition, cleaning processes can be quite job-specific, be it the cleaning of air ducts, treatment and prevention of graffiti, maintenance of various types of surfaces or basics like chewing gum removal.

For cleaning companies, such training makes economic sense, too. For instance, without this knowledge, they will not be able to realistically device a price structure upon which to negotiate a cleaning contract. As for the prospective clients, most will recognize that it is best to go with a professional outfit to minimize the risk of ending up with a whopping bill on restoration works for a botched-up job.

“Lack of know-how among property managers is the primary cause of poor maintenance of buildings,” says Dr Pomfret. “They get incompetent cleaners and these people destroy the properties.

So the management has to cough up money to do yearly restoration and refurbishing.” Business owner Bill Thompson agrees. “The notion that a mop and bucket is all you need to clean is archaic”. In most developed countries, cleaning has become a highly professional field. In fact, the ‘First World Facility, Third World Mentality’ complaint from visitors regarding the U.A.E. amenities can be attributed to the fact that cleaning as a process has been hugely neglected.

“The industry must become professional in the shortest time possible. As a matter of urgency, a body comprising the Government, local and city councils, training schools, suppliers, contractors and other stakeholders should be set up to draw up minimum standards,”

Pomfret says, some 20 years ago, I helped develop the 5 Star Health and Safety Management System the first part I concentrated on, was housekeeping “Cleanliness and Order” this gives the employer, the biggest bang for the buck.

Arguing that Governments should be more receptive and exposed to the cleaning service industry, Pomfret – whose company has been in the health and safety business for over 40 years – says: “Right now, it’s a free-for-all. Unless standards are imposed and cleaning contractors are certified and classified, many countries will continue to be plagued by poor maintenance and dirty surroundings.

“Dr. Pomfret may remind one of a young Don Aslett, the author of numerous books on cleaning techniques and self-styled No. 1 cleaner in America, but all he dreams of is a day when no person would fear to walk into a public toilet in any country he has trained.

Meanwhile, his center has trained staff from companies in the Philippines. The going has been tough, still is, principally because of the need for him to relentlessly prod and irritate people into action, even just to see the urgency of the matter. On the positive side, he can be likened to a grain of sand in an oyster, which will one day become a pearl – and be appreciated. DR CLEAN’S DIAGNOSIS INDUSTRY MUST BE RATIONALISED: Nobody can tell for sure about something as basic as the size of the industry. There are so many players but numbers don’t guarantee quality. And there are no proper guidelines to qualify cleaning enterprises for bids to undertake a cleaning and building maintenance job.

Without guidelines on such things as a company’s manpower, technological and management capacity as well as know-how, anyone with minimal or zero knowledge can bid for contracts. Unlike in the construction industry where contractors are graded, there is no classification of cleaners based on professional competence.

THE CLEANERS THEMSELVES MUST BUCK UP

Cleaning know-how and cleaning product knowledge are not fully pursued by cleaners. Unlike the UK and Singapore, which imposes practical and theory tests on would-be cleaning operatives (questions range from which chemical to use on which type of surface to which color pad to use for which scrubber machine for which function), most western countries cleaning service industry operates based on: “even my grandmother can do that job”. WHAT STANDARD? There are no established standards for cleanliness.

Lack of education on the part of the authorities (such as local councils), building owners and property managers and employers, as well as the cleaners themselves is a major obstacle against the much-needed professionalisation of the industry. “Our architectural and engineering ability has reached the point where we can build the world’s tallest buildings, but our cleaning and maintenance ability has lagged far behind.” >

WHAT BENCHMARK?

There is no benchmark for players to strive to match and maybe exceed, with a view to promoting the development of the International cleaning service industry to the level where it can compete in the international market and export cleaning services. “The Government should nurture the industry so that it will reach that level.”

Bio:

Dr. Bill Pomfret; MSc, FIOSH; RSP. FRSH; CHCM; RSP;

Managing Consultant; Safety Projects International Inc.

Can be contacted at

26, Drysdale Street, Kanata, Ontario, K0A 3M0.

Tel: 613-2549233.

e-mail: pomfretb@spi5star.com