Hazardous area classification (HAC, formerly electrical area classification) impacts the design and operation of petroleum, chemical processes, and other industrial operations that utilize flammable materials in potentially ignitable atmospheric concentrations in air by requiring ignition source controls.

Hazardous area classification (HAC, formerly electrical area classification) impacts the design and operation of petroleum, chemical processes, and other industrial operations that utilize flammable materials in potentially ignitable atmospheric concentrations in air by requiring ignition source controls.

Uncontrolled ignition of in air can result in loss of life, property damage, business interruption, a negative impact on communities, and legal liabilities. There are numerous regulations used in a variety of industries to address hazardous area classification. Not only is it important to select the appropriate code, but the findings of the classification analysis need to be documented.

A hazardous area can be defined as any location where there is risk of an explosion. But every hazardous area is different, and each has specific requirements depending on the nature of the atmosphere and the elements that are present.

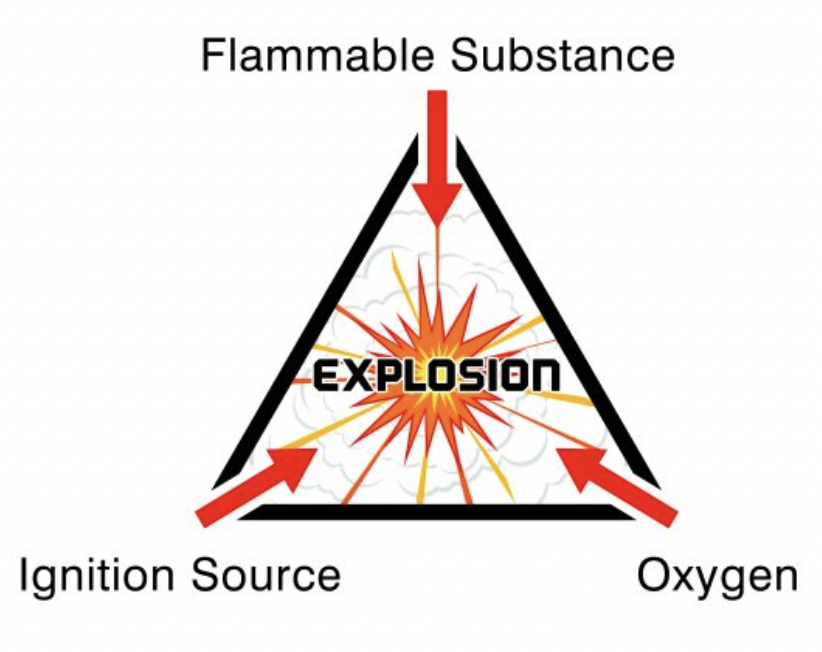

Fundamentally, for an explosion to take place, flammable or explosive gases, vapours, mists or dusts will be present.

Then, the level of risk of an explosion is based on the frequency and duration of the occurrence of an explosive atmosphere.

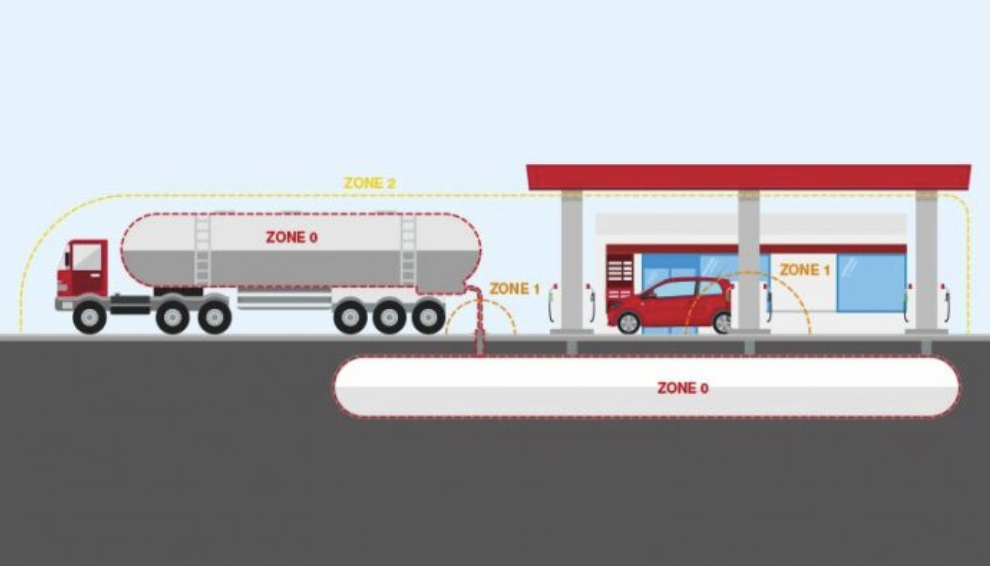

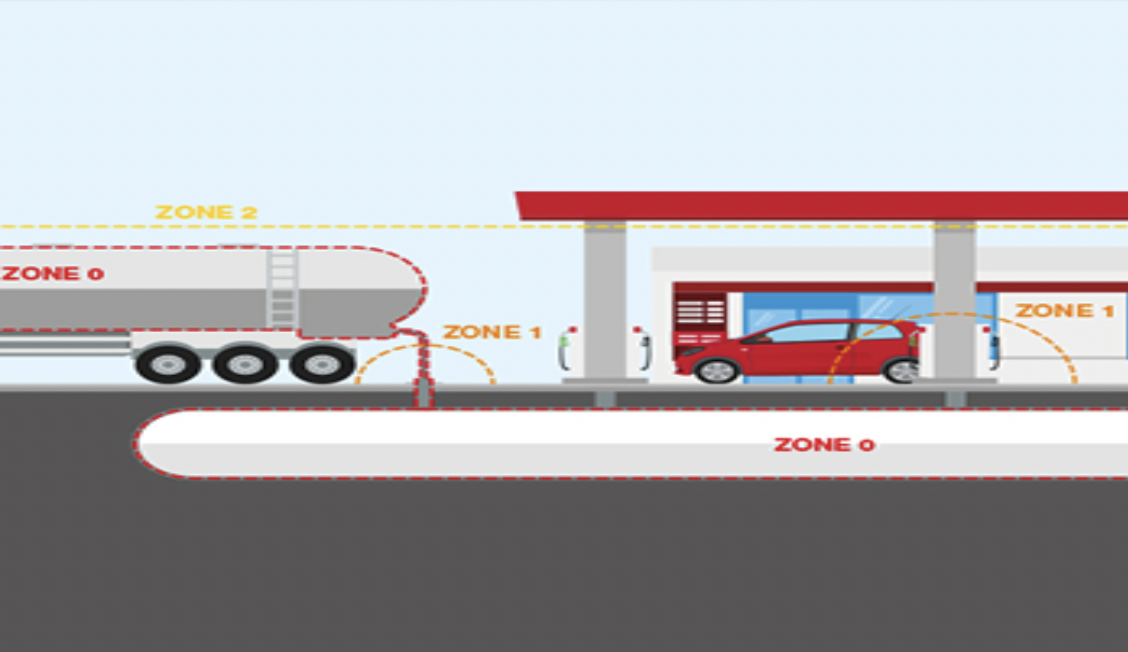

This level of risk is represented by classifying the hazardous area as Zone 0, Zone 1 or Zone 2 (for gas, vapour and mist atmospheres) or Zone 21 or Zone 22 for dust atmospheres.

In this article we will look at what defines Zone 0, Zone 1 and Zone 2 hazardous area classifications and the considerations for specifying lighting into each area. But first, we must consider what is likely to cause an explosion in the first place.

There are three necessary components for an explosion to occur;

- Flammable Substance– this needs to be present in a relatively high quantity to produce an explosive mixture (e.g. gas, vapours, mists and dusts).

- Oxygen– oxygen is required in high quantities and in combination with the flammable substance to produce an explosive atmosphere.

- Ignition Source– a spark or high heat must also be present.

Where there is potential for an explosive atmosphere, special precautions are needed to prevent fires and explosions. Electronic equipment, including lighting, needs to be purpose designed for use in hazardous areas to prevent a spark occurring and igniting any flammable substances.

Although every application is different, for the ease of monitoring and specification each hazardous area is classified as a particular level or “zone”. As a result, all hazardous area equipment must be designed with hazardous area zone classifications in mind, as the “zone” governs the level of protection and precaution required. It is essential to know which zone you are working in, so that you can specify the most appropriate equipment.

For gases, vapours and mists the zone classifications are recognised as Zone 0, Zone 1 and Zone 2 areas. Let’s look at what defines each zone…

Zone 0

Zone 0 is an area in which an explosive atmosphere is present continuously for long periods of time or will frequently occur.

Zone 1

Zone 1 is an area in which an explosive atmosphere is likely to occur occasionally in normal operation. It may exist because of repair, maintenance operations, or leakage.

Zone 2

Zone 2 is a place in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only. These areas only become hazardous in case of an accident or some unusual operating condition.

To make this even easier to understand, look at the diagram of a typical petrol station below where we have identified the areas that are classified as Zone 0, Zone 1 and Zone 2.

Whenever you are filling up your tank you are standing in a Zone 1 hazardous area. That is why the use of mobile phones on petrol forecourts are banned. You’re phone isn’t rated for use in hazardous areas. Have a think about it next time you’re filling up!

It is essential to install a range includes dedicated luminaires for both Zone 1 and Zone 2 areas as well as industrial applications. The colour of the luminaire body indicates the level of protection. Zone 1 fittings are supplied as silver, Zone 2 as dark grey and industrial fittings as white. All emergency versions, whether Zone 1 or Zone 2 can also be easily visually identified by their red end cap, encapsulating the emergency battery back-up.

The part codes for each variant also differ depending on the level of protection required A Zone 1-part code begins SPX, Zone 2 SPZ and industrial products having a SPI prefix.

Most company’s do not currently offer any lighting solutions for Zone 0. This is because Zone 0 usually classifies areas for gas storage or containment, and any lighting required would be used on a small and portable basis for visual inspection, e.g. a headlamp, rather than a dedicated fixed luminaire.

Therefore, it is very important to make sure that you are using a suitable luminaire for your application by choosing your fitting based on its suitability for the Zone in which it will be located…

Dr Bill Pomfret; MSc; FIOSH; RSP. FRSH;

Founder & President.

Safety Projects International Inc, &

Dr. Bill Pomfret & Associates.

26 Drysdale Street, Kanata, Ontario.K2K 3L3.

www.spi5star.com pomfretb@spi5star.com

Tel 613-2549233