In the early 2000s, a young Chinese pianist named Lang Lang was scheduled to perform at New York City’s Carnegie Hall in a highly anticipated debut. At the time he was considered by many critics to be the most exciting keyboard talent in a generation.

In the early 2000s, a young Chinese pianist named Lang Lang was scheduled to perform at New York City’s Carnegie Hall in a highly anticipated debut. At the time he was considered by many critics to be the most exciting keyboard talent in a generation.

In the months leading up to the concert, Lang Lang practiced for countless hours. Given the recent reception to his work, his confidence was sky high, and he felt certain he would showcase his virtuosic playing in front of an adoring audience.

But on the day of the concert, he made a critical error. During his warm-up routine, he rushed through his pieces and paid little attention to the details critical to the music. He didn’t practice the nuances so important for flawless execution. In his own words later, he admitted he didn’t take the time to connect with music as he normally did.

Not surprisingly, his performance fell dramatically short of expectations. He played too fast, missed notes, and lacked the emotional depth and nuance that had put him on the map in the first place. His overconfidence convinced him he didn’t need to prepare by practicing the details. After his sub-par performance, he vowed never to make that mistake again.

Source: Bill Pomfret

Practicing or rehearsing prior to performance is something nearly everyone does. Reading through a speech, reworking calculations, organizing ingredients, jotting down notes, testing the work surface, firing up the machine. Good practice breeds confidence and reassures the mind. It also primes the brain, getting it ready to perform.

It is easy to overlook the need to practice the details essential to a great performance. Yet, it is precisely the smallest parts and pieces of any performance that require a fresh and recent rehearsal. Getting the details right in the warm-up encourages a repeat performance when things go live. Replicating the finest details is always easier than engaging them without a recent practice. The devil, as they say, is always in the details.

Behind every brilliant performance lie the nuances and details great performers slave over. Don’t forget them during the warm-up. Details are the difference that makes a difference.

Whether it is a pianist performance or the delivery of health and safety training course, attendees deserve the very best performance you can deliver, if you fail to prepare, be prepared to fail.

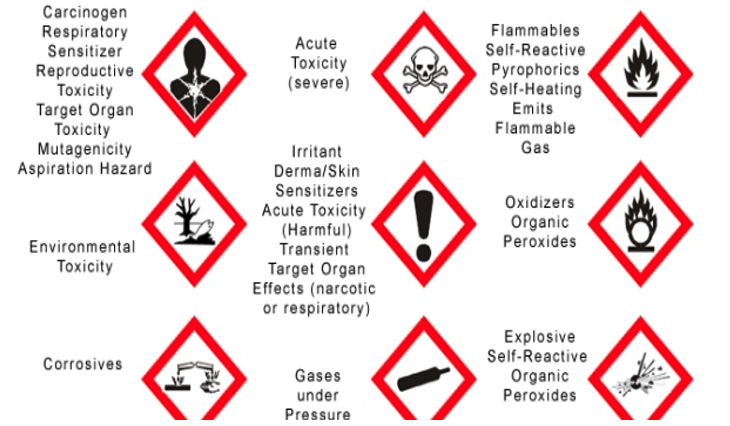

Health & Safety can be achieved only by informed, alert and skilful people who respect themselves and have a regard for the welfare of others.

Every accident has a cause, and every accident causes a loss, no-one in Industry today can escape the duties, obligations and rights created by the ever-increasing government legislation, health & safety at work is a subject in which everyone, at every level, has a direct interest.

Depending on your point of view, there are human factors, legal and cost considerations, all which demand understanding, effective communication, implementation and above all effective training.

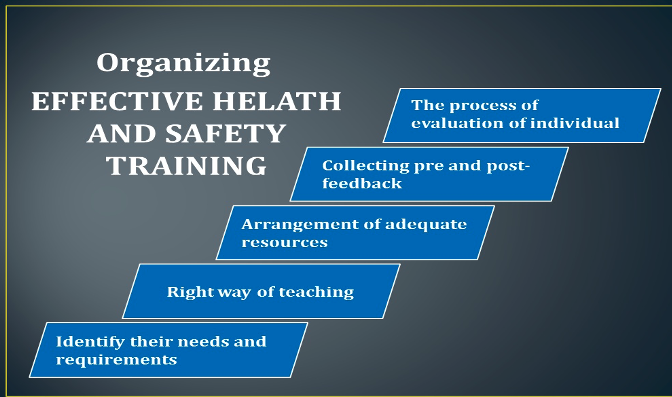

Running a safety training course may sound simple—just get in front of trainees and teach them what they need to know. But the devil is in the details, and there are endless complications and mitigating factors that influence how training goes.

How to Become a Master of Safety Training is dedicated to untangling these issues and spelling out what goes into making a good safety training session, from the trainer’s presentation skills to the organizational climate and beyond. If you want to deliver top-notch safety training, these are the areas you need to master.

If you want to get where you’re going, you must know where you’re starting from. And when it comes to health & safety training, that means knowing yourself.

The most fitting place to start is by taking an honest inventory of your knowledge and abilities. Give yourself a grade on the following skills and know-how on a scale of A to F.

Look at your grades. Does anything stand out to you? Take a moment to congratulate yourself on any spots where you stand out. And make note of any areas where you could improve—

Research. Spend some time researching what makes someone good at a specific skill. Make a list of all the small elements or subskills that make up that skill set. For example, if you want to be a better safety presenter then your list may include public speaking skills, creating more engaging PowerPoints, and working on connecting with the audience using personal stories. These are the areas you should focus on.

Practice. Naturally, we covet mastery of skills but there’s often a reluctance to put in the effort to attain success. As most people know from experience, wishing for things does not make them a reality. Getting better at things requires work, but it doesn’t have to be grueling if you plan it right. Once you’ve got your list of subskills, it’s time to start working on them one by one.

Reassess. After you’ve put in the practice, reassess where you’re at. If you’ve improved a little bit, then keep at it because you’re making progress. If you now have a good grasp on a particular skill, then it may be time to move on to the next one. And if you aren’t improving as much as you’d like, it may be time to go back to the research phase to make sure you’re focusing on the right skills. Be patient with yourself as you work on these skills. Remember, skills improvement takes time, but if you put in an honest effort then you’ll get there.

Many people think they’re “safe enough” and will never be injured. If you can find a way to tie in safety training to their family—like how wearing PPE properly will set an example for their kids to follow—then workers will be a lot more interested in the training. Learn how to leverage family safety to improve workplace outcomes.

Not everyone is excited to attend health & safety training. That doesn’t mean they can’t be engaged once they’re in the classroom—but it does require you to put in some effort to meet them on their terms.

Most safety training happens for compliance reasons: because a box needs to be checked or it’s recertification time. But employees don’t care that legislation requires them to sit through training.

So, forget about telling them why they must attend training and start telling them why they should want to start paying attention. Emphasize the benefits of training to them. Offer real-life examples they can relate to. Tap into what motivates them to get up in the morning (even if it’s just getting through their shift so they can provide for their family) and use it to motivate them to pay attention.

Every time you start preparing for safety training, look at that note. Are you repeating the same-old safety training in the exact same way as last time? If so, your training is going to be dead in the water. People will pay less attention than they did last time, and it could lead to a serious injury or fatality as a result.

Find some way to shake it up. Consider adding a couple different types of activities or making time for social learning. Rejig your PowerPoint and handouts. Mix up the order in which your present information.

Obviously, you still need to cover all the mandatory bases. But you need to do your best to make it come across as new. It can take more time and effort, but the payoff will be worth it.

Sometimes, you’ll find yourself freshening up the same old training for what seems like the thousandth time, and it will feel like you’re just putting lipstick on a pig. And that’s totally fine because you know what will catch people’s attention? A pig wearing lipstick.

One sure-fire way to make yourself more relatable is to inject a bit of humor into your safety training. Even if you don’t have a single funny bone in your body, you can learn to use some core principles of humor to improve your safety training.

You won’t find the word “perfect” anywhere in this article (… except in that last sentence.) That’s because safety trainers may need to be a lot of things, but the P-word isn’t one of them.

For one reason or another, too many safety trainers try to avoid making mistakes and they end up limiting their ability to connect with the audience. The best safety trainers are relatable—they talk like a human, using conversational speech instead of reading technical jargon off a piece of paper, and they focus on being relatable rather than trying to deliver a flawless TED Talk.

They also recognize that they’re talking to humans. Trainees will get distracted, their minds will wander, they’ll forget things. It’s an inevitable fact of safety training. Offering a bit of grace as you marshal their attention back to the lesson can earn you a lot of appreciation.

Safety training typically happens in the classroom. This is a shame because the value of safety training is put to the test in the workplace. So why not more closely connect learning and practice by teaching the lesson where it will be used?

Whenever possible, your safety training should focus on not only telling workers what to do but to show them how and where it’s done too.

Instead of giving trainees another video to watch, handout to read, or lecture to listen to, get them out in the workplace. Rather than giving them a list of lockout/tagout protocols, walk them through what each step looks like on the machines they use every day. In lieu of discussing hypothetical hazards, walk around the shop floor and point out actual hazards in the wild (or where hazards have appeared in the past). Even if you can’t get out of the classroom, you can at least include real-world examples in your lessons that workers must deal with in their day-to-day lives.

The goal here is to help workers apply knowledge as they learn it. There are two main benefits to doing so. First, it cuts down on the amount of memory required because they can see it or put it into action right away.

Second, learning is often contextual, and lessons can better sink in when they’re taught in the same place where the knowledge will be applied. (This is why it’s a lot easier to learn how to drive when you’re sitting behind a steering wheel rather than in a classroom.)

Source: Pomfret

Keep in mind that there likely isn’t time for proper one-on-one training with individual employees. That’s why it’s so important to get your supervisors to provide employees with additional coaching as necessary in the weeks and months following training.

Learning is a process, not a one-off event. It would be great if you could teach workers something once and then—voila! —they know it for the rest of their lives. But people learn at different speeds, they pick up parts of training but not others, their memories are fallible.

Often, they need to encounter the same lesson in a variety of contexts before it fully sinks in.

Which is why your training should include healthy doses of reinforcement through toolbox talks, safety posters, and direct interventions.

As you prepare for upcoming health & safety training, you should take a few minutes to plan for how you will remind workers about their safety lessons. What visual reminders can you put up around the workplace to trigger employees on new safety concepts? What can you discuss in toolbox talks to reinforce what was taught in training?

Here’s one of the most overlooked aspects of reinforcing safety training: supervisors and other leaders (including you) can have quick one-on-one conversations with workers throughout the workday. These informal chats should be used to prompt workers to put safety lessons to use, to talk about what they learned in training, and to help identify where there may be a gap in safety skills or knowledge that can be addressed before an incident occurs.

There’s no substitute for practice. There’s also no such thing as too much practice. When trainees do something repeatedly, their brain forms new pathways that make it easier to perform that action in the future—their brains are literally rewired.

The hierarchy of controls places a great deal of importance on engineering solutions, and offering plenty of opportunities to practice safety skills is the best way to re-engineer people’s brains and alter their actions in the workplace.

This also means that it’s but not all practice is equal. In fact, safety habits only develop if people are paying attention to what they’re doing. Having a conversation with a co-worker while fiddling with a fall arrest harness won’t help forge new habits and is a poor way to learn how to do a new task

Wherever possible, encourage a focus on the task at hand while practicing. incumbent on safety managers, supervisors, and other frontline leaders to offer one-on-one coaching when possible. Positive reinforcement can also go a long way to keep up motivation over the long haul of habit development. And creating a safety climate in which workers feel psychologically safe to correct, and be corrected by, their co-workers and superiors can super-charge safety habits development, remember, habits start as cobwebs, and finish as cables.

As we’ve seen so far in this article, there’s a lot more to running an effective health & safety training program than just putting butts in seats. You need to make sure trainees have a chance to discuss and practice new skills, learn in social contexts, and have their learning reinforced in the weeks and months following training.

Source: Pomfret

An organization’s supervisors are its eyes and ears on the ground. They can notice safety issues and intervene before they get out of hand. They can provide timely reminders to workers, reinforcing positive actions and offering corrections when necessary. They can also offer safety managers an accurate assessment of how well safety training is sinking in—and whether any follow-up training is required.

All of this is within the scope of most supervisors’ roles, but it rarely comes naturally to supervisors, and these aspects of the job are often overlooked. This means you’ll have to offer some encouragement and coaching to supervisors if you want to get them on board. It can take a fair amount of work but turning them into safety champions is worth the effort.

At its core, creating a safer workplace means reducing the number of errors that could lead to injury. But as we all know, not all errors end up getting someone hurt—safety folks track near misses because they know that they’re a good indicator of problems, and they do a decent job of pointing to the source of potential safety issues.

Close calls aren’t the only type of leading indicator. There are tons of non-safety errors that may also signal that workers are acting in a way that, if left unchecked, could lead to an injury or fatality. And to find them, you only need to peek at the operations department.

Ask your colleagues in operations whether mistakes being made result in issues with productivity or quality. Look at the various KPIs that are tracked by many production/ operations leaders. These errors could be precursors to larger safety issues, and noticing a pattern of individual mistakes could help you tailor safety training to address those problems, which would allow you to proactively head off potential safety concerns before they arise.

There’s another major benefit to all this: you’ll be doing a huge favor for the operations manager, because if you’re able to address the issue then you’ll be solving problems in both of your departments.

The one big caveat is that you’ll likely have to drill down to the common causes of safety and production errors. Typically, this means zeroing in on the big stuff and implementing training on human factors and other awareness-based issues that apply to issues that affect every department.

Any good driver will tell you that they adjust how they drive based on weather conditions. The same should be true for safety trainers, who should adjust each session based on the organizational safety climate.

Most safety practitioners are familiar with safety culture, which is the set of norms, habits and values that govern how things happen in a safety context in the workplace. Culture is big, influential on safety outcomes, and almost impossible to change overnight. Safety climate, meanwhile, is what’s happening on any day: a near-miss happened the day before and everyone’s talking about it, or a supervisor delivered a good toolbox talk at the start of the shift and employees are on their game. If culture is the weather pattern, then climate is whether it’s sunny or raining today.

Paying attention to the safety climate will make it a lot easier to meet your employees where they’re currently at and then lead them to where you want them to be.

Most people don’t realize it, but individual employees have their own safety systems. This is one of the reasons why it’s important to take a 24/7 approach to safety. Because how safe employees are at home is just as important as how safe they are at work. In the 40+ years of delivering safety training, we’ve also learned that teaching workers to keep their loved ones safe at home and on the road will improve outcomes in the workplace too.

Safety training determines a lot more than whether workers get injured or not. It also has an impact on how well people follow company procedures. It influences culture. And it affects how productive people are. An effective safety program can make workers better at their jobs.