The European Union, the United States, and Canada all have strong regulations and directives for managing substance control. China, Japan, and Korea each have their own similar governing frameworks that address these concerns. Developing nations are following suit and leveraging these frameworks to build their own regulations. The following interview Jim Kandler of GE illustrates these key points:

The European Union, the United States, and Canada all have strong regulations and directives for managing substance control. China, Japan, and Korea each have their own similar governing frameworks that address these concerns. Developing nations are following suit and leveraging these frameworks to build their own regulations. The following interview Jim Kandler of GE illustrates these key points:

Developing comprehensive substance compliance programs that meet requirements worldwide is complex. How long have you been involved in building and managing substance compliance programs, and what are some of your experiences?

I’ve been involved deeply with substance compliance programs for the last six years. I was drawn to it because I got to a point in my career where I realized that I wanted to leave a better legacy behind for my efforts. I used to work in the medical device industry and I saw environmental stewardship as another way to leave a positive legacy.

It started when I was in college, I got fed up with watching products constantly fail because of how they were engineered. I noticed Timex watches would fail like clockwork within twelve and a half months. Firestone tires were blowing out. The list just goes on and on. I knew in medical device, they wouldn’t take these risks and things would be engineered better. I moved to the medical device industry because I knew they had to design things that couldn’t just stop working because a company wanted to sell more. Lives are at stake. In medical device, it’s about helping people. Environmental substance patrol was a natural extension and next step for me.

This last year, I finished one of the best projects I worked on to date. I was responsible for GE Healthcare’s product redesign effort to get ready for the EU ROHS inclusion of medical devices in July 2014. I was part of the core team setting up working practices and procedures. It was my job to collaborate across all the GE divisions and come up with one source of truth for all the common parts. There was a need for a central group in the company to collect compliance data from all suppliers. Without that one common group, GE might have had twenty-five individual teams requesting the exact same data from all of the GE suppliers at the same time. In my role, we worked on securing and maintaining 150,000 part declarations. Having a single group for all of GE took the noise out of the program.

Why do companies need to consider measuring the progress of their substance compliance programs?

Well, it’s simple, if you don’t measure a process then you can’t improve it. Some people just scramble to collect these declarations. It’s often thought of as a compliance only effort but the truth is that it’s a core business process and it has cost, time, and quality associated with it. It needs to be measured in order to baseline performance and determine adjustments. How else would we identify opportunities for improvement?

One thing that seems to get forgotten is that if your customers, resellers, and partners are asking for compliance declarations for your company’s products and they aren’t getting them in a timely manner than it can reflect negatively on business going forward. I’ve been in situations where sales people have come to me looking for substance declarations in order to close a deal.

Companies who want to be profitable in the future are using positive news about compliant with various regulations as a way to position themselves with customers and employees they want to have in the future.

What are some of the metrics a company might use to measure the progress of their compliance program?

There are six common metrics I use when evaluating a compliance program. They all tell you something different about what is happening in your process.

- Cost of declaration – The cost of obtaining a declaration is important, if cost is a parameter your senior management cares about. Cost is nearly always top priority for program initiation. Companies tend to have finite budgets for compliance programs. Resources are often tight, so compliance managers need to learn how to most efficiently leverage their budgets. Cost drives a lot of decisions.

- Number of declarations collected – Keeping an accurate count of the number of declarations collected within a certain cadence is important for understanding your throughput and where you might have blocks in your process. Metrics can be set up to count declarations daily, weekly, monthly, and yearly to help track the progress of your program. This is important because it helps companies decide how to efficiently manage the pile of work in front of them each day. This also enables the numbers to be rolled up into a dashboard for reporting.

- Number of parts added and changed – One of the toughest parts of the job is that parts are continuously being added and changed and requiring new declarations. If a company is not keeping up with this, it’s likely they will be blindsided. For all they know, they could be adding new parts and changes faster than they are collecting the declarations. This could result in negative progress over time. Changes to a part can add a lot of extra work. This is due to new products, cost reduction work, general part obsolescence, or parts that are no longer available.

- Percent of needed declarations collected – This is a detailed way to look at progress and to take into account the total process overall. You can only add a certain percentage of work on top of the work that you already have based on the resources available. This changes as the program matures. Towards the stabilization phase of a compliance program, the team may be in maintenance mode and the job is only to maintain the pace of collecting declarations for a steady flow of part declarations.

- Number of parts escalated – Escalation comes from exceptions that occur. This is very common, and can impact between 20-30% of parts that are on the list. Escalations happen for different reasons, a lot have to do with issues on the supply side or with company data that prevents you from getting a declaration.

- Average cycle time in days – It’s important to know the cycle time for collecting declarations due to working with immovable deadlines and a fixed team size. This will tell you if you can get your declarations in the time available to you and help you to identify whether or not to be more aggressive with addressing exceptions.

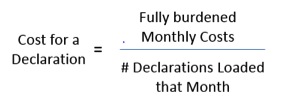

There is a formula that I use and it seems fairly obvious. The average monthly cost of a declaration is equal to the fully burdened monthly costs divided by the number of declarations loaded that month.

How can using these metrics benefit companies building or maintaining substance compliance programs?

The metrics are a good way to better understand how the compliance programs and processes are supporting the business. It enables companies to make sure that the programs are being run efficiently and to reduce costs where there are opportunities. It also gives a good view of issues that may exist with suppliers and whether or not compliance deadlines will be met. It’s also a way to express the need for budget increases with factual data. Ultimately, it should enable the corporate strategy and revenue projections by removing obstacles to sales and preventing stop shipments, fines, and fees.

How should companies get started?

Use the formula to figure out how much it is costing to obtain declarations and benchmark that against industry average costs to find out whether or not the declaration cost is high, low, or middle compared to peers. Look for additional opportunities to reduce costs and construct a Pareto chart to figure out which efforts are most beneficial. Make sure to understand corporate objective and business drivers. If it more important to reduce costs by 50% or is it more important to respond to customer requests within 90 days? Compliance has to be 100%. Determine how long it takes to be 100% compliant and what it costs to achieve it.

Bio:

Kelly Eisenhardt is Co-Founder and Managing Director at BlueCircle Advisors, an environmental compliance and sustainability consulting and training firm based in Massachusetts (www.bluecircleadvisors.com.) In her role at BlueCircle Advisors, she is responsible for providing business intelligence, strategy and implementation of environmental, social and governance (ESG) risk programs. Her experience aligns well with her client’s needs for technology, compliance, and sustainability expertise by helping companies create and manage their corporate environmental and social responsibility programs.

To contact Kelly Eisenhardt, send emails to kelly.eisenhardt@bluecircleadvisors.com or follow her on Twitter @KelEisenhardt. For more information about BlueCircle Advisors and the company’s products and services, please visit www.bluecircleadvisors.com, on Facebook at BlueCircle Advisors, on Twitter @OurBlueCircle, and on the LinkedIn group at the BlueCircle Advisors group.