This is the second CERM Insights article in a series about the application of Cascade Effect Thinking and tools to mitigate risks and transform them into dramatic improvements and even disruptive innovations for small, mid-sized and very large organizations.

This is the second CERM Insights article in a series about the application of Cascade Effect Thinking and tools to mitigate risks and transform them into dramatic improvements and even disruptive innovations for small, mid-sized and very large organizations.

More than a million ISO certified companies will have to integrate risk management with a risk assessment. We detail a case study how this can be done using quality risk tools. Four of 40 possible cascading risk assessment and management tools are demonstrated in this case study: Gamified Process Risk Mapping, New Process Wish List, Cascading Risk Map & the Future State Process Map.

In 2013, Euro Image Inc. a Florida car repair shop and dealership was in serious trouble. Although the business survived the 2007-09 financial crisis, they were just limping by. Their past recipe for success was no longer working. Angel Rodriguez, the owner/manager had not received a paycheck in two years. He was ready to close the business and start over in his garage. However, he dreaded the prospect of laying off his employees, including friends and family.

Launching the “Saving Angel” Project

In a last ditch effort, Angel asked for help. David Patrishkoff had extensive experience facilitating business transformations for multinational companies. Angel told his employees that the 4-day event would determine the fate or new direction of his business.

Identifying and Transforming Cascading Threats into Renewed Profitability

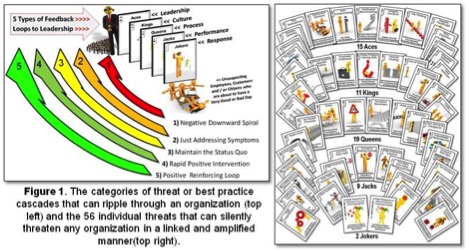

Angel learned that there are 56 common cascading risks that can silently ripple through, threaten and even destroy a business. The risks are categorized as flawed leadership decisions, ineffective work culture, process flaws, performance issues, bad responses to critical situations and absent learning feedback loops. This cascade is illustrated in Figure 1.

The identification and transformation process is gamified to engage employees and diffuse defensive obstacles that can get in the way of needed business changes.

Before the business transformation could begin, Angel had to understand five key principles:

- When things go wrong, blame flawed business processes, not the people.

- If you put good people in a bad process, the bad process wins, every time.

- Every organization sows its own self destructive cascading seeds. They must be discovered, disarmed and continually monitored.

- Leaders must initiate the first steps to create a high performance work culture and achieve process excellence.

- When a business is suffering, leaders must look in the mirror, not out of the window, to assign blame or create excuses.

In preparation for the business analysis, David wallpapered all four walls in Angel’s conference room using large rolls of paper. Two walls were dedicated to detailed process risk mapping of the core business activities. (Figure 2)

This examination provided a detailed report card for each process step in the business. Individual measures included identifying; the percentage of tasks done right the first the time, task duration, non-value added activities, re-do loops, errors in vehicle diagnosing, lost revenue through missed sales opportunities, order change inefficiencies and causes of costly warranty issues.

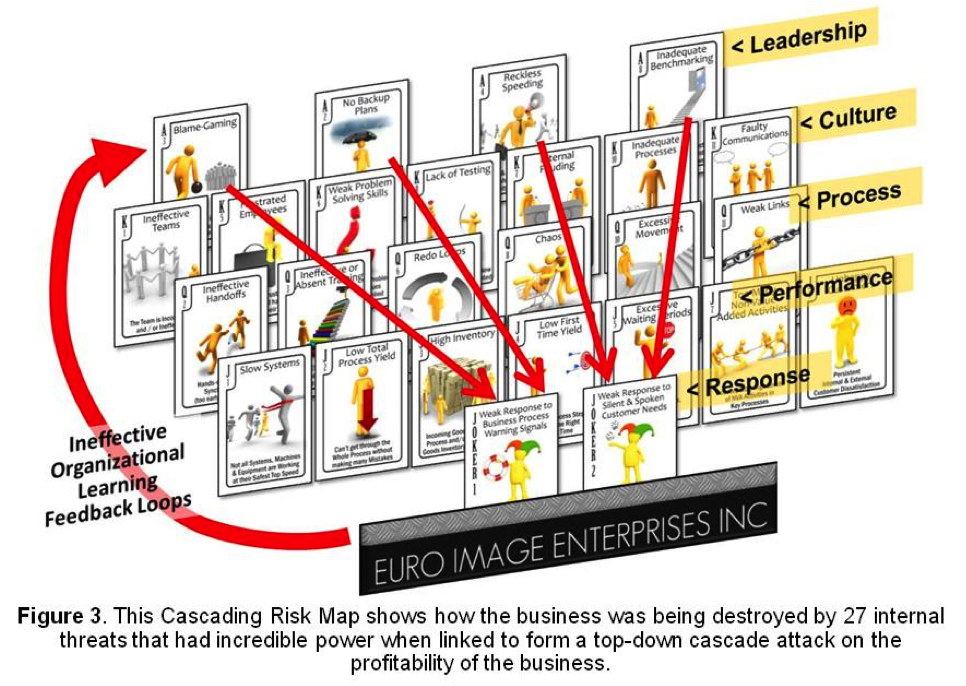

The Cascading Risk Map (Figure 3) identifies the presence of 27 of the 56 possible internal threats. They were silently impacting Angel’s business for a long time. Individually, each threat was considered a minor irritation. However, collectively they created an almost unstoppable and destructive cascading force.

The third wall (not shown) was reserved for a “Wish List” of actions to address cascading threats and inefficiencies. They were sorted by short, mid and long-term activities.

The last wall (Figure 4) was reserved for the new agreed upon business process that would quickly bring Angel’s business back to profitability.

Mission Accomplished

On the last day of the event, a detailed 43-point action plan was created from the Wish List. That afternoon, employees were summoned to the conference room. Angel informed his employees that the business would not be closed; a recovery plan, involving each employee, would be initiated immediately. Best of all, no one would lose their jobs, benefits and work hours would not be cut. Within a week, Angel had implemented 1/3 of the action plans which immediately increased revenue and profits. One week after the rapid improvement event, Angel’s company was able to write him the first paycheck he had seen in 2 years.

Bio:

Bio: David Patrishkoff is President of E3 – Extreme Enterprise Efficiency® and the Founder of The Institute for Cascade Effect Research®. He is a Lean Six Sigma Master Black Belt, Adjunct Professor for Kettering University Master’s Degree Programs and the inventor of a Cascading Risk Management Methodology. Prior to starting his consultancy in 2001, David held many worldwide senior executive positions in the automotive and trucking industry. Author email: david.patrishkoff@cascadeeffects.com