Fault tree analysis (FTA) is a technique used to explore the many potential or actual causes  of product or system failure. It is best applied when there are many possible ways for something may fail. For example, when my car doesn’t start, it could be a dead battery, a faulty starter, a loose wire, an absence of fuel, and on and on.

of product or system failure. It is best applied when there are many possible ways for something may fail. For example, when my car doesn’t start, it could be a dead battery, a faulty starter, a loose wire, an absence of fuel, and on and on.

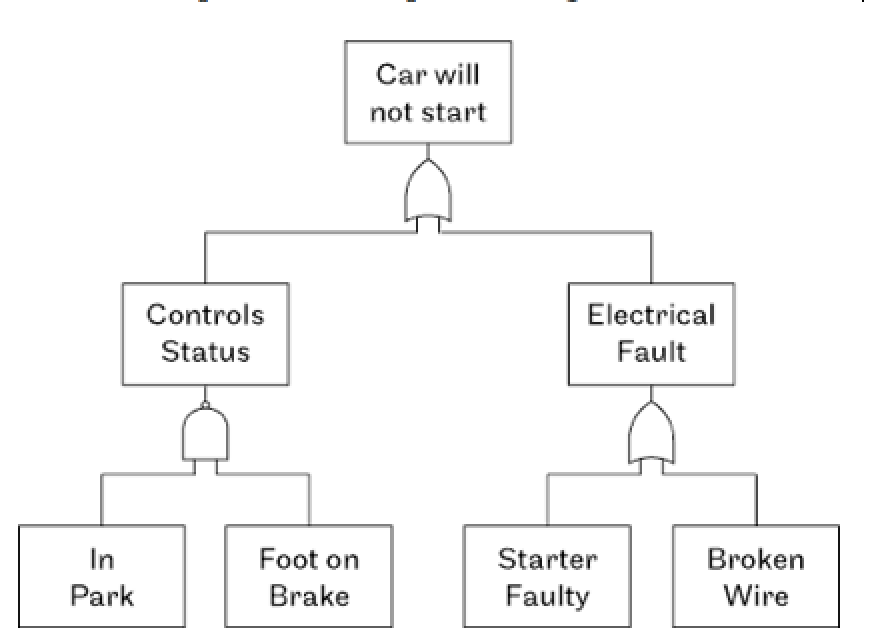

FTA is a top-down analysis method, where we start with a symptom (e.g., the car will not start), then list the many possible causes in a structured manner. The tree aspect of the name comes the various branches that may lead to the symptom.

Here’s a simple FTA example showing the basic structure:

From the top block (Car will not start), which is the experience I had when trying to start my car, this diagram lists two possible ways in which this failure may occur. If the controls are not in their proper position, meaning that both the car has to be in park and my foot has to be depressing the brake, then the control status will indicate that the car is not ready to start.

Electrical faults is another path, as could be the fuel system, or other systems and parts in the ignition sequence. Here the FTA lists only two possible causes, either of which may prevent the car from starting.

Why to Use an FTA

Of course, the FTA can become rather complex. The idea is to build the FTA to help organize a complex set of paths to failure. Generally, if there are a few to many possible causes or combination of causes that lead to the top-level symptom, then an FTA helps to organize and visualize the ways in which a system can fail.

An FTA may include probabilities. Using a little math help the team identify the most and least likely paths to failure. In this way the FTA helps prioritize work to improve the system reliability.

When to Use an FTA

An FTA has many uses. It can help the design team during the concept or development phases craft a system design that minimizes potential failures. Used in combination with a failure modes and effects analysis helps the team think though and mitigate potential problems that lead to system failure.

An FTA is also helpful when analyzing failures. When a failure occurs during a simulation, prototype testing, or in the hands of the person using the product, an FTA provides a means to evaluate and quickly identify the most likely root causes of the failure. This is particularly handy for the support teams when working with customers that have experienced a failure.

A third use of an FTA is in cases when the probability of each element of the potential causes gets updated using actual field data. Then the team can use the FTA to evaluate which elements to improve that will have offer the greatest reliability improvement. This can be a focal point for ongoing product improvement or the design of the next generation of products.

FTA helps in the planning, management, and improvement of a product and is best used with complex systems that have many possible failure mechanisms. It’s a tool to add to your reliability plan.

Bio:

Fred Schenkelberg is an experienced reliability engineering and management consultant with his firm FMS Reliability. His passion is working with teams to create cost-effective reliability programs that solve problems, create durable and reliable products, increase customer satisfaction, and reduce warranty costs. If you enjoyed this articles consider subscribing to the ongoing series at Accendo Reliability.