Old industries are dying and new ones are rising. We have seen Amazon destroy the book stores, Uber transform the transport industry and Netflix make a video store a fond memory.

Old industries are dying and new ones are rising. We have seen Amazon destroy the book stores, Uber transform the transport industry and Netflix make a video store a fond memory.

Today’s technological disruption is fast and ruthless and it is transforming most of the industries. But I think we are behind supply chain if you compare the disruption happening in other functions like marketing and finance and it is time to focus on key supply chain trends.

Then you are maybe not up with the latest fad. But fads are one thing and trends are another. Fads come and go but trends have the potential to become a powerful influence for long term change.

So what are the 7 big supply chain trends that you need to be aware of so that you don’t become a dinosaur in your own lifetime as a supply chain professional? I call them “Supply Chain 7.0”

7 Supply Chain Trends to Watch

7 Supply Chain Trends to Watch

So what are 7 big supply chain trends that you need to be aware of as a supply chain professional?

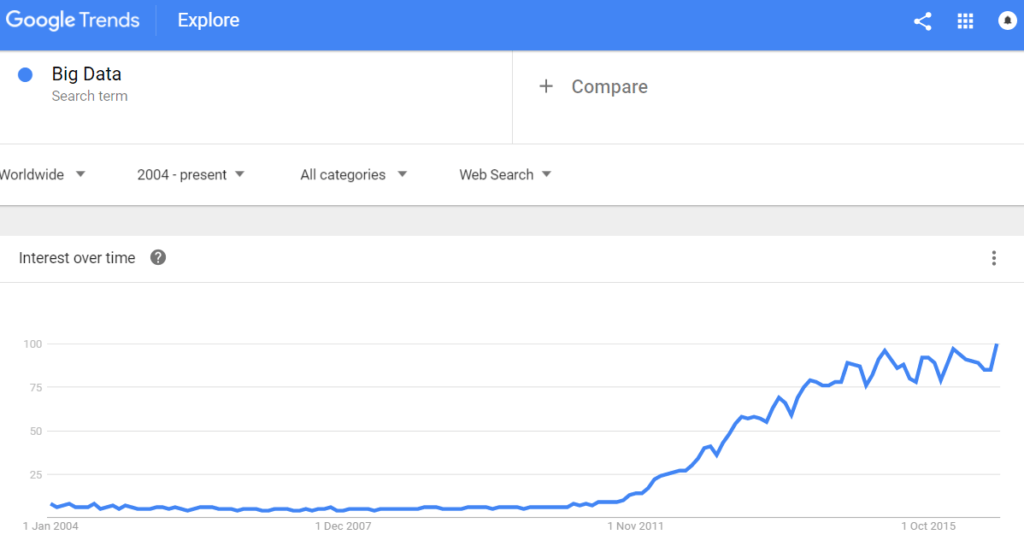

#1. Big Data will be big force you can’t ignore

Although “Big Data” has become a contemporary buzzword, it has significant implications supply chain, and presents an opportunity and a challenge to most industries. What makes Big Data unique is its:

- Velocity: in real time

- Variety: the data varies in time and in context, and is not a fixed data model to real time

- Volume: the volumes are significant and require unique approaches

Volume can occur in many ways. There is more data because, among other reasons, the data is captured in more detail via current ERP & other software packages. For instance, instead of just recording that a unit sold at a particular location, the time it was sold and the amount of inventory at the time of the sale is also captured. Moreover, long global supply chains necessitate data capture at multiple points in the supply chain. In addition, there is now a proliferation of consumer sentiment data resulting from Tweets, Likes, and product reviews on websites. Such data must be analyzed and quantified.

The rise of the Big Data is a hot supply chain trend as revealed by Google Trends. In fact the rate of interest in this term I would classify as “breakout” .

Do supply chain folks have strategy for big data analytics?

The examples of potential applications of big data within logistics and supply chain would be:

- Manufacturers can advise customers about improved notification of delivery time, and availability; based on historic and current manufacturing data.

- Freight carriers can reliably advise time of delivery, factoring in weather, driver characteristics, and time of day and date of arrival.

- Retailers can forecast and understand customer sentiment data and use of mobile devices in stores

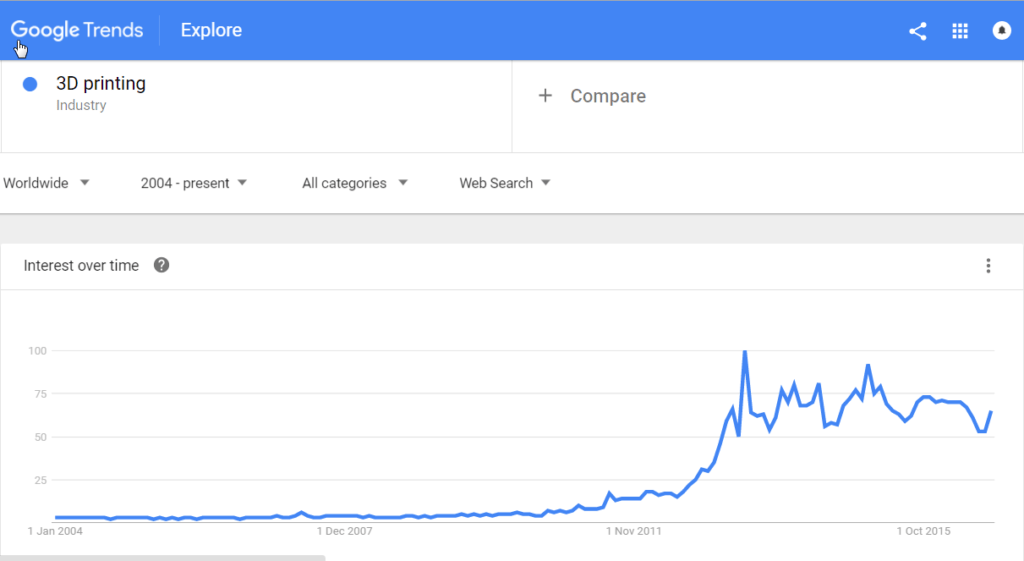

#2. 3D Printing is now needed to support product life cycle

Where does 3D printing fit in today’s supply chain trends? And what is your company doing to fully leverage this powerful and surprisingly versatile innovation?

3D Printing has been around for 3 decades and generally using additive manufacturing, however, commercialization at mass level still has to take off. It involves fabrication of products through the use of printers which either place layer upon layer of materials or employee lasers to burn material, resulting in a finished design.

Today 3D Printing is used within several industries such as used for making medical implants, jewellry, customized football boots, lampshades, racing-car parts, solid state batteries and customized mobile phones

While much has been said and written about the impact of 3D Printing, it is only now it is being used as a term in its own right as its interest is continuing to increase in trending as we can see in Google Trends:

What are the potential applications which impact supply chain?

- Manufacturing the inventory of long tail “C Class” items to support customers at the end of product life cycle.

- Providing vendor managed 3D Printer at customer site by providing the software designs for products which customer can on demand as a licence or pay-per-print basis.

- By providing design data to customer encourage customer to print using online its like shapeways or sculpteo so they can print as and when needed.

The key benefits for supply chain

- Drastically reduce lead time and increase on-time delivery performance by closer provision of parts by installing printers on customer site

- Simplify supply chain network

- Reducing space requirement in warehouse

- Reduce Excess & Obsolete for high variety and low volume items.

- Faster prototyping and samples

- Agile and response supply chain to shorter product life cycles.

- Possibly cheaper products to make and purchase for low volume items

- Supply chain can support greater customization

- And many more!!

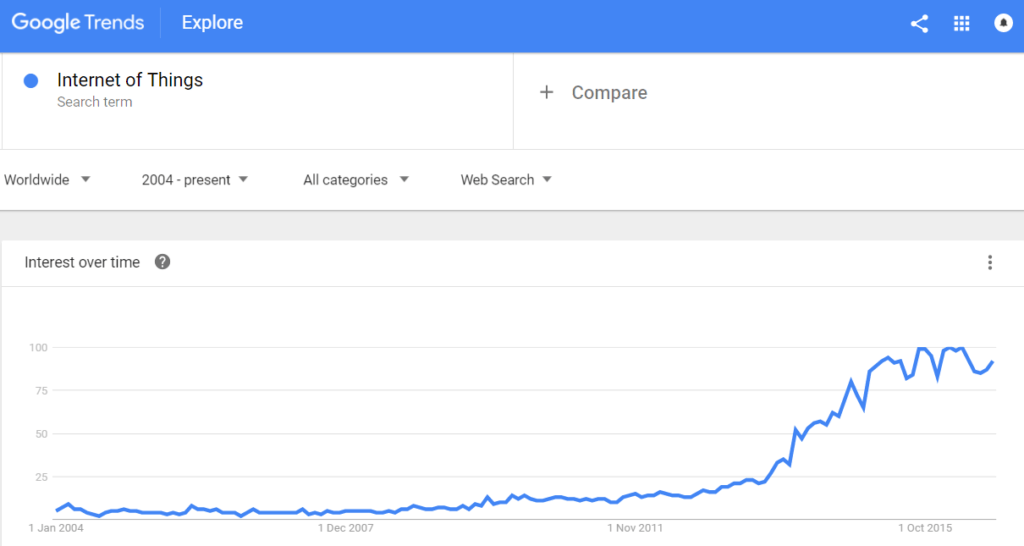

#3. Internet of Things (IoT) – Industry 4.0

Can Internet of Things aka Industry 4.0 be a force for faster growth in an increasingly digital global economy? Most people who know about this will emphatically say “Yes”. Why such optimism? The IoT can boost productivity, drive the emergence of new markets, and encourage innovation.

What is the Industrial Internet of Things? The Internet of Things is the industrial application of a network of physical objects that contain embedded technology to communicate and sense or interact with their internal states or the external environment. In manufacturing, connected sensor networks already monitor logistics movements and machines such as mining equipment and entire utility plants, helping organizations reduce costs through more efficient operations. As a term its interest is still trending up.

The Internet of Things is driven by an expansion of the Internet through the inclusion of physical objects combined with an ability to provide smarter services to the environment as more data becomes available. Various application domains ranging from Green-IT and energy efficiency to logistics are already starting to benefit from the Internet of Things concept. There are challenges associated with the Internet of Things, most explicitly in areas of trust and security, standardization and governance required to ensure a fair and trustworthy open Internet of Things which provides value to all of society.

#4. Moving supply chain to “Cloud”

Cloud computing can help your organization to realize major benefits by redefining traditional supply as it’s computing facilitates enhanced responsiveness to supply chain disruptions. Moreover, new technologies and service providers make it possible for companies to turn their supply chains into end-to-end business operating strategies. The connected cloud enables the real-time collaboration that makes this possible.

How can cloud-based computing make supply chains more competitive?

Cloud-based application can make supply chain to be more connected, Intelligent, Saleable and Rapid. The notable benefits could be:

- Real-time visibility: supply chains become more dynamic, secure and interactive

- Seamless collaboration: supply chain capabilities are harmonized beyond physical boundaries

- Actionable insights: innovative data analysis supports advanced decision-making

- Maximum efficiency: integration of people, process and technology

- Organizational flexibility: digital plug-and play enablers provide natural “configure and re-configure” capabilities

- Enhanced responsiveness: using better information and sophisticated analytics to interpret and react speedily to disruptions, including demand and supply signals

- Proactive prevention: decision support, driven by predictive analytics, helps to confirm reliability and rapid adaptability

- Last mile postponement: swift repurposing of organizational assets at short notice helps to ensure that supplies always meet changing demands.

#5. Gamification of supply chain

User adoption and the efficiency of future procurement systems will benefit from gaming methodologies. Such systems will give companies to assume a competitive persona, utilizing reward based psychology inherent in gaming to drive user behavior in the purchasing, logistics or materials management scenarios.

#6. Use of Artificial Intelligence (AI) and machine learning in supply chain

Imagine MRP runs over night send PO to supplier based on a parameter setting, then send a reminder email before due date and if supplier is late call a supplier contact in the voice of “Siri” to ask why they are late and when they will actually deliver! Possible? I think very much possible even with existing AI and machine learning capabilities.

Artificial intelligence (AI) existing for some time and was introduced to develop and create “thinking machines” that are capable of mimicking, learning, and replacing human intelligence. Since the late 1970s, AI has shown great promise in improving human decision-making processes and the subsequent productivity in various business endeavors due to its ability to recognize business patterns, learn business phenomena, seek information, and analyze data intelligently. Despite its widespread acceptance as a decision-aid tool, AI has seen limited application in supply chain management as we stand today, but I think this will eventually become a mainstream technology in next decade or so.

#7. Augmented reality (AR) will soon be in your office

Most smart phone and mobile devices has some sort of app which deals with augmented reality (AR). Supply Chain systems integrated with AR devices could allow a buyer to point their smartphone at a product and receive instance information about its availability, pricing options, delivery time, lead time and more. AR could possibly become a way on how business can order their stocks, finding alternatives for out of stock items and download the information pack and data sheets. I think AR is probably the most under rated prospect amongst other supply chain trends.

Conclusion

You can mentally get all this but the biggest challenge to embracing innovation and disruption these technologies will bring in your supply chain design. Forgetting old habits and adopting new, can be big challenge. And that would be the issue in adopting these supply chain trends.

John Maynard Keynes had this to say about change and innovation. “The difficulty lies not so much in developing new ideas as in escaping old ones”

This will mean a life of continuous learning.

It doesn’t mean going back to university but consuming online training, reading blogs and even attending online webinars. Killing old habits means a force fed diet of new information and ideas.

Bio:

Dr. Muddassir Ahmed is a Manufacturing Operations, Procurement and Supply Chain leader from international multi-site manufacturing experience in Electrical, Hydraulics and Internet industries. With considerable experience in deploying Continuous Improvement best practices in Europe, Middle East & Africa. You can follow his blog muddassirism.com or contact him on Twitter, Facebook or Linkedin.