The reliability of a product is strongly influenced by decisions made during the design process.

The key message here is reliability occurs at the point of decision. Each time someone makes a decision, selects a component, chooses a material, assumes a use profile, the eventual product reliability takes shape.

The key message here is reliability occurs at the point of decision. Each time someone makes a decision, selects a component, chooses a material, assumes a use profile, the eventual product reliability takes shape.

Design for Reliability, DfR, is about making good decisions across the organization concerning reliability.

The Design for Reliability Process

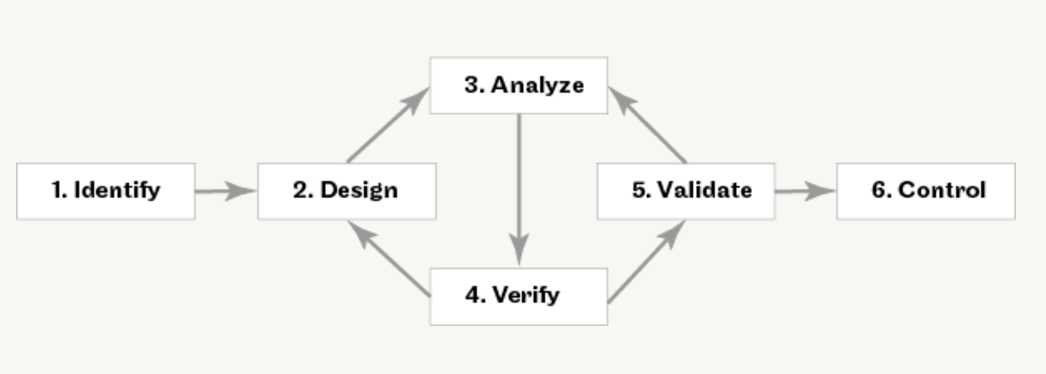

Figure 7.2 Design for reliability (DfR) activities flow, from Practical Reliability Engineering, outlines the basic stages or elements of a product generation process

The six stages span a typical product lifecycle from concept till retirement. The process steps each include a slightly different focus and set of tools. Let’s briefly examine each step in turn.

The six stages span a typical product lifecycle from concept till retirement. The process steps each include a slightly different focus and set of tools. Let’s briefly examine each step in turn.

1. Identify – Goals, Requirements, Specifications, Expectations

The decision during the early stages of product development set the framework of goals, objectives, requirements, and specifications. These documents guide the decision making for the remainder of the process.

Understanding and documenting the customer expectations for reliability performance includes:

- Functional and performance requirements

- Environmental and use profile descriptions

- Duration and Probability of Success expectations

Tools include:

- Benchmarking

- Environment and use studies

- Quality Function Deployment (QFD)

- Risk Assessment Studies

- System Reliability Modeling (RBD, FTA, STA, Petri Nets, Markov, etc.)

2. Design – Creating a Draft Solution

The decisions during the design and development stages involve:

- Material selection

- Component selection

- Industrial design

- Human factors design (user interface and interactions)

- Electrical and Mechanical drawings

- Software/Firmware development

The decision bound the potential future reliability performance. The DfR tools during this stage focus on enabling each member of the team to make decisions which fully consider the impact of future reliability performance.

Tools include:

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD) modeling

- Mechanical and Electrical performance modeling

- FMEA, FMECA, FTA, Hazard Analysis

- Stress-Strength Analysis, Derating Analysis

- Tolerance Analysis

- Hazard and Operability Studies (HAZOPS)

- Reviews of part, material and process selections

- Non-material failure modes, common cause failures

- Critical to Reliability/Quality list

- Overstress Protection

- Degradation Protection

- Design Reviews

- Design Review Based on Failure Modes (DRBFM)

3. Analyze – Examine the Solution

During the design process, there may be outstanding questions to address. Such as an uncertainty concerning the degradation of a coating over time, or the capability of the desired component vendor to meet tolerance requirements.

Many of the tools employed during the design phase also provide a means to refine understanding concerning reliability. FEA, for example, is an essential tool for physics of failure modeling and use.

If material samples, coupons, rough subsystem prototypes are available, initial evaluation, experimentation, characterization may begin.

The focus is to explore, discover, and reveal the design weaknesses in order to allow design changes to improve the product robustness.

Another part of this step is to check and refine the understanding of the customer environment and use conditions. As the design takes shape the team is likely to discover potential failure mechanisms that require additional environmental and use condition information.

Often new products are an evolution of previous products. The use of past field and warranty data provides insights on how the range of selection elements of a design individually and interactively respond to customer use conditions.

An output of the analysis is a refinement of the areas of focus during the verify step. Areas of high risk or uncertainty may receive additional scrutiny. Focused or refined measurements provide clearer information for decision making.

4. Verify – Checking the Solution Against the Specifications

This step starts the examination of the question: Is the design meeting the specifications?

If all is well executed to this stage the design and analyze steps created and refined a product that meets the set of specifications created during the first step of the process. Products are complex. The verify step often finds additional elements of the design requiring improvement.

The information provided includes new failure mechanisms (HALT and margin testing), refined estimates of durability (ALT), and patterns of performance deflation (degradation analysis). The information allows the team to determine if the design meets the internal specifications and likely will meet customer expectations.

A couple additional tools are:

- FRACAS

- Sample Size Calculations (statistics)

- Waterfall test sequencing

- Document/Configuration Control

- Measurement System Analysis

5. Validate – Checking the Solution with the Customer

The decision during this step requires customers. Does the product meet customer expectations? This is one way to view validation, another is a detailed refinement of the verification process. Either way, the intent at this point is to make sure the design and process to create the product based on the design results in products that perform as the customer expects.

The same basic set of tools used during verify may take part in the validate step, yet may focus on customer specified evaluations or production variation concerns. HALT, HASS, ALT, FRACAS, etc all may play a role.

Some customers may require or expect a reliability growth or demonstration testing as part of the validation step.

6. Control – Monitoring and Improving

The decisions during this step focus on supplier and production stability and capability. Plus, the information coming back from customer provides a means to identify potential design or process improvement projects.

The work in this step begins as the team establishes the supply and production processes. It takes shape beginning during the design step and becomes refined as data and information become available.

Tools such as SPC, control charts, and process capability studies focus on monitoring variation and adjusting or improving to reduce or maintain an acceptable amount of variation.

Tools may include:

- Process FMEA

- HASS

- ORT

- Testability analysis

- Maintainability analysis

- Failure analysis of field returns or production failures

- Customer surveys

- Call center data analysis

A DfR Summary

The basic process is to focus on understanding the customer reliability expectations well enough to enable the creation and production of products that meet or exceed those expectations. Identifying the right set of specifications enables the team to design, analyze and verify while making decisions that shape the reliability performance.

The steps of design, analyze, and verify may occur sequentially or simultaneously (or nearly so). The iterative process of framing decisions, gathering information and checking assumptions and results permit the team to evolve the design to meet expectations.

DfR is not one tool or analysis, it is many. More importantly, DfR is focused on enabling everyone in the organization to make decisions that support the goal of meeting customer reliability expectations.

Bio:

Fred Schenkelberg is an experienced reliability engineering and management consultant with his firm FMS Reliability. His passion is working with teams to create cost-effective reliability programs that solve problems, create durable and reliable products, increase customer satisfaction, and reduce warranty costs. If you enjoyed this articles consider subscribing to the ongoing series at Accendo Reliability.