1. INTRODUCTION

Risk, value and cost are terms that have been especially prevalent in quality management literature over recent years. A recent review of over one hundred years of published writings relating to quality revealed them to be themes that always underscored much of quality theory and practice. While references to the economics of quality have remained quite consistent over that time, however, value and risk are keywords that have substantially increased in their occurrence during the present century.

Risk, value and cost are terms that have been especially prevalent in quality management literature over recent years. A recent review of over one hundred years of published writings relating to quality revealed them to be themes that always underscored much of quality theory and practice. While references to the economics of quality have remained quite consistent over that time, however, value and risk are keywords that have substantially increased in their occurrence during the present century.

Value: Value Engineering was discussed in the early 1960s as the delivery of functionality relative to cost. Michael Porter introduced the ‘value chain’ concept in the mid-1980s [1], whereby value was seen as something that was added at each step in a production process. A growth of interest in lean during the 1990s catapulted the term to even greater prominence, and customer value is now very widely discussed in relation to its flow throughout the ‘value stream’.

Risk: As with value, risk is not new and has always been a primary concern of quality management (QM), often under different names. Risk has for decades been identified, managed, mitigated and reduced via the control of variation and uncertainty, regulatory compliance, formalised quality systems and procedures, and tools such as Failure Mode and Effect Analysis (FMEA). More recently, however, high-profile events such as the ‘Y2K’ fears, the 2008 Global Financial Crisis, the 2012 European beef supply chain scandal, a slew of major product recalls, and now the global disruption created by COVID-19 lockdown have propelled risk to the very forefront of management concerns. ISO 9001 and ISO 31000 have over recent years redefined risk as the effect of uncertainty on objectives and emphasised the vital importance for organisations of adopting risk-based thinking.

Cost: Managing costs has always been very explicitly discussed as a primary objective of quality, with the ‘economics’ of quality featuring in the earliest writings by quality pioneers such as Shewhart, Dodge & Romig, Deming, Juran, Feigenbaum, Crosby and others.

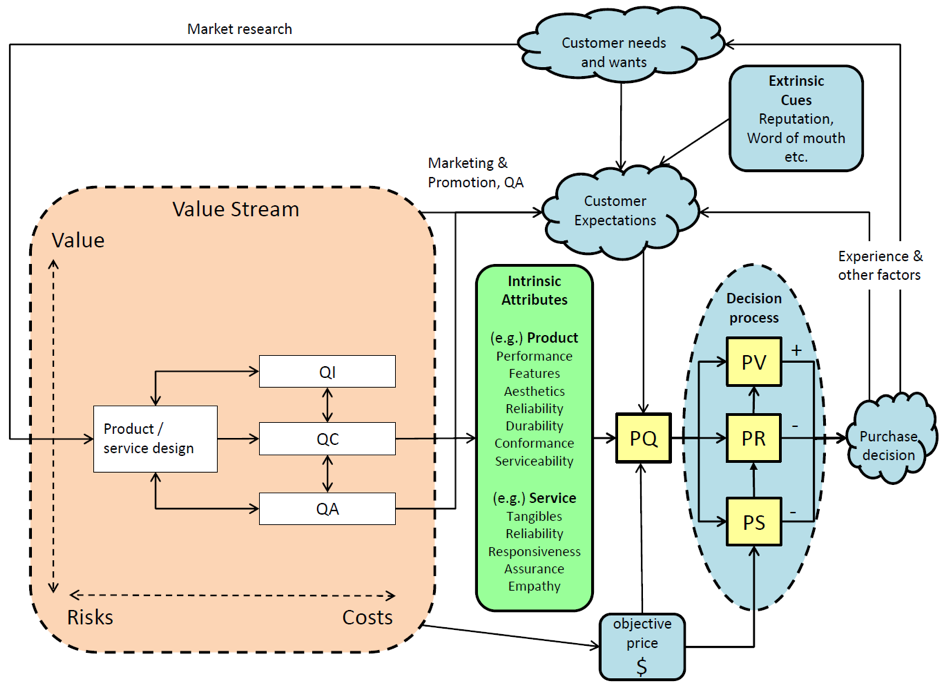

All three are of importance, and considering the dynamic interplay between these concepts led me to re-conceptualise quality as a continuous balancing-act between (1) creating and delivering customer value, while (2) controlling and reducing risks, and (3) managing costs across the entire value stream from design through to the purchase decision and beyond. This resulted in a model which I have labelled the QVRC (Quality, Value, Risk and Cost) model of quality (figure 1).

Legend: QA = Quality Assurance, QC = Quality Control, QI = Quality Improvement, PQ = Perceived Quality, PV = Perceived Value, PR = Perceived Risk, PS = Perceived Sacrifice

2. THE PRODUCER SIDE (LHS) OF THE MODEL

Beginning on the producer (light orange, left hand) side, the producer of a product or service aims to create an output that can be produced or delivered, and that a customer will want to pay for. The design process is intended to create both the product/service and the system to deliver it. Feeding into the design process as inputs are the stated or unstated needs and wants of the customer/market. To help with the design process we can employ a range of quality-oriented tools such as FMEA, Quality Function Deployment (QFD), Design for Six Sigma (DfSS) and many others. These methods are themselves oriented more towards value addition, risk management or cost control, meaning that methods can be used that align well with the value/risk/cost (V/R/C) profile of the intended product or service.

In managing the production system (the value stream), the producer aims to create the (designed) value while minimising inherent risks and operating costs as far as possible. Again, the producer can call upon a wide range of quality tools and methods to help with this. For example, lean can help identify value flow and sources of waste (or risks to value flow). Quality control (QC) can minimise unwanted variability (uncertainty – also a form of risk) that costs money and detracts from value. Quality assurance (QA) can provide confidence to customers that systems are compliant, robust, well designed and being used, and so allay their concerns about potential risk. Quality improvement (QI) can seek continually reduce potential for risk and cost within the system. At all points, the producer can use the costs of quality as a guide to the effectiveness of the above.

3. ATTRIBUTES OF THE PRODUCT AND SERVICE: CENTRE OF THE MODEL

Certain ‘intrinsic’ attributes can be used to verify objectively that the product/service meets design specifications and customer expectations. The attributes shown at the centre (green area) of the QVRC model are those developed by David Garvin [3] for products, and by Parasuraman, Zeithaml and Berry [4] for services. These and other attributes (since there are many others, for different product/service types) can be measured with either producer or customer-derived data. For example, reliability can be assessed as mean time to failure (MTTF) and can be communicated to the customer to allay fears of early failure (risk) relative to similar products. Performance, features, durability etc. can be promoted as components of value (e.g. water resistance to 300m). Thus, these attributes are the interface between producer and consumer. The QVRC model can be adapted to apply to different product/service types by changing the intrinsic attributes appropriately.

4. THE CUSTOMER SIDE (RHS) OF THE MODEL

The customer (towards the right hand side of the model) has needs and wants (of which they may even not be fully aware) driving their receptiveness to purchasing a product or service. They will also have expectations about the product or service they want to buy based on ‘extrinsic cues’ such as advertising, marketing, word-of-mouth communications, user testimonials, web reviews or past experience with similar products. These, together with the intrinsic attributes mentioned above and the objective price, will be primary determinants of the perceived quality (PQ) of the product/service. The prospective customer will balance the value, risk and cost associated with buying the product/service (the yellow boxes). They will consider buying a product or service that provides them with some value (perceived value, or PV). If the perceived price is not a significant barrier, the customer will also consider any perceived risks (PR) associated with purchase. Cost is only one of these risks and is often termed ‘perceived sacrifice’ (PS). Perceived risks for the consumer include that a product might break, wear out, become quickly outdated, fail to deliver as expected and so on. If the balance is favourable to the customer, he or she will likely buy the product/service. It is important to re-state that these dimensions are entirely unique to every single person (hence they are subjectively ‘perceived’).

5. USE OF THE MODEL

The QVRC model has several potential uses:

A) As a framework for positioning products and services

Products and services have differing V/R/C profiles, and customers also have individual, unique perceptions of value, risk and cost. The model encourages producers to consider the profile of their product/service and seek to understand the customer profile. To give a service example; the provider of a tourist bungee-jumping operation might want to provide the appearance of risk in order to provide the consumer with the memorable thrill (value) that they are looking for. But the provider must also ensure the risks inherent within the process are actually minimised, through extensive and rigorous safety protocols and related checks. As another (product) example, the value proposition of the Japanese ‘fugu’ pufferfish is a fine and refined flavour, coupled with the fact that the dish is rare and potentially deadly due to the tetrodotoxin (hundreds have died from eating fugu over the years, including those who have been fraudulently sold it at markets as a different fish!). Great expertise is required in its preparation, implying that the dish is considered refined and exclusive. For the legitimate restaurateur, hiring suitably qualified and experienced chefs is vital, as is ensuring that all appropriate protocols are in place (including the basic legal food safety compliance systems) to appropriately match the risk factor from the product. This will add cost, but the customer expects to pay more for this delicacy, and higher cost is merely part of the perceived value bundle.

B) As a framework for selecting quality design and management tools and methods

There are dozens if not hundreds of possible quality design, management, control and improvement methods available. If a manager knows that the primary aim of their process is reduction of risks in the product (such as dairy products, where safety is a basic expectation of the consumer) then methods such as quality standards, FMEA and statistical process control become of relatively greater utility than certain others. Other methods are still useful, of course, but may not achieve risk control to the same extent. Alternatively, if high levels of flexibility and product customisation are of primary importance, then lean or agile will be valuable methods to pursue at an early stage.

C) As a quality teaching / training aid

While the model does not aim to provide a complete model of total quality management, it has value in showing students how value AND risk AND cost flow simultaneously throughout the value stream, from design through the purchase decision and beyond (e.g. servicing and repair). All require some level of attention and managing. The relevance of various QM methods and tools to these quality objectives then becomes more evident and this allows the student to understand how (and how much) a tool contributes to one or other objective.

Bio:

Dr. Grigg has been involved with quality management for over thirty years. He started at IBM’s PC manufacturing plant in the West of Scotland and worked as a quality engineer for a major supplier to the Rolls Royce and Boeing before becoming an ISO 9001 internal auditor. In 2016 he became a Professor of Quality at Massey University. He has written over 260 articles. He is a Fellow of the Charter Quality Institute, a senior member of ASQ, a director and former president of the New Zealand Organisation for Quality and an active supporter of the Australian Organisation for Quality. He is also the Associate Editor of the Routledge journal Total Quality Management and Business Excellence and a member of the New Zealand national reference group of TC176 (ISO 9001)

References

[1] Porter, M. (1985) Competitive Advantage: Creating and Sustaining Superior Performance. New York.: Simon and Schuster.

[2] Grigg, N. (2020) Redefining quality in terms of value, risk and cost: a literature review, International Journal of Quality and Reliability Management.

[3] Garvin, D. A. (1984). What does ‘product quality’ really mean? Sloan management review, 26, 25-43.

[4] Parasuraman, A., Zeithaml, V. A. & Berry, L. L. 1988. SERVQUAL: A Multiple-Item Scale for Measuring Consumer Perceptions of Service Quality. Journal of Retailing, 64, 12-40.