If you have ever participated in, performed, or been audited by an internal auditor or 3rd party registrar in relation to a documented quality system, you have most likely encountered a dreaded nonconformance.

If you have ever participated in, performed, or been audited by an internal auditor or 3rd party registrar in relation to a documented quality system, you have most likely encountered a dreaded nonconformance.

A short list of examples of these nonconformances that we are all familiar with include but are not limited to: The revision on the control plan does not match the revision on the work instructions, the operation number on the PFMEA does not match the one on the control plan, employee training records do not match the change level of the procedure, the released document is not the latest approved level, the instructions do not provide enough information for the employee to perform their duties consistently or correctly, or the control plan does not match the latest drawing or engineering release level

When similar nonconformances are found in your organization, what are your auditors really telling you? Maybe a better question is, “Why do auditors neglect to focus on the systemic failures at the source of these issues?”

When similar nonconformances are found in your organization, what are your auditors really telling you? Maybe a better question is, “Why do auditors neglect to focus on the systemic failures at the source of these issues?”

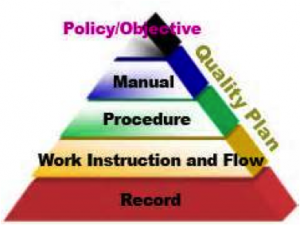

Let’s explore these nonconformances from a different point of view. When you break them down, most all nonconformances in a documented quality system can be consolidated into three distinct categories. Each of these categories can be viewed as risks within your documented quality system and each may be targeted for risk reduction focusing on the failures rather than the results of the failures. These three categories are as follows: Inconsistencies, Inaccuracies, and Inadequacies.

INCONSISTENCIES

Inconsistencies within your documented quality system can normally be reduced by focusing on technology. An example of this can be seen in companies that use Excel, Word, PowerPoint, etc. to document their procedures, control plans, FMEA’s, work instructions, and other controlled documents where the documentation contains multiple entries for the same data. If a company has several documents that must be updated when changes occur, the opportunities for failure increases immensely. However, a database driven system that requires only one data entry field which is shared between all related documents greatly reduces those inconsistencies.

INADEQUACIES

The risks for inadequacies are most commonly associated to training. If your auditor asks an employee a question they cannot answer, he or she must assume that the system they are auditing is inadequate to provide that employee the information necessary to perform their assigned duties at the expected level. When we discuss training at this level, we are also including the training of the management team responsible for setting up the quality operating systems and knowing what must be included to assure that the system is robust. Many times, assuring that job functions, responsibilities, and expectations are fully outlined in the job descriptions can assist these efforts.

INACCURACIES

The final risk we will discuss is inaccuracies. Inaccuracies, in some cases, can be driven by technology (as mentioned above for inconsistencies), training (as mentioned above for inadequacies), and discipline. For our purposes here, we are going to focus on discipline since both inconsistencies and inadequacies should be targeted for risk reduction prior to inaccuracies. Once both inconsistencies and inadequacies are properly managed, you will find that most inaccuracies will be caused by discipline issues. Discipline includes the commitment from the management team to provide the time and resources necessary to achieve the desired results. To target inaccuracies related to discipline, we need to look at the structure of the quality operating system and ask if the system is designed to eliminate the possibility of inaccuracies from occurring. The discipline to design a robust system, implement the system, provide the training necessary, and then hold employees accountable are the risks to be managed in order to reduce or eliminate this type of failure.

As most Black Belts will tell you “Variation is the enemy”. This phrase is not confined to the manufacturing process. Variation may also be looked at from the theory of complexity or opportunities for failure. Any time you can reduce or eliminate a source of variation, you will reduce the complexity of the system and eliminate a source of risk. An example of this would be in the proposed changes to the ISO 9001:2015 standard and the elimination for the need of a quality manual. This is an opportunity to remove a source of variation. If your quality manual references procedures or other documents, a risk will always exist in that a change in your system could be in conflict with the original document.

All too frequently, companies have been advised, forced, or perceive that they must document their systems to the point where anyone who walks in off the street should be able to read their documented quality system and perform every task needed to keep the operations going. This is a myth that has been perpetuated by customers, auditors, and people within the organization by misinterpreting the actual expectations. The more a company can document their training efforts and prove the effectiveness of the training through conformance to expectations, the need for documentation may be reduced.

Most all documented quality systems can benefit from reviewing the actual need for documentation, opportunities to combine documents where redundancy exists, and identifying non-essential information that is being distributed.

One example of this that always comes to mind is a company I visited that had over 120 work instructions for their inventory management system. When asked why they had all of these, they indicated it was the expectation of their auditor. I then asked to look at the built-in help file in their inventory management system. Almost everything they had documented in their work instructions was contained in that help file. They now have three work instructions and reference the help files as applicable.

By reducing the variation in your documented quality system by assessing the risk for the three categories listed above and then focusing on reducing these potential risks, along with assessing the actual need for documentation, you will find you can achieve substantial progress in realizing a world class documented quality system.

Bio:

Ed Grounds is a Six Sigma Master Black Belt who founded ISP Software, Inc. in 1997. ISP Software, Inc. offers quality information system software products, training, and consulting services primarily targeting manufacturing organizations which are designed to improve their efficiency and profitability. His diverse background and over 30 years of experience with quality operating systems uniquely qualified him for the development of the quality information system products offered by his company. Mr. Grounds has been retained to provide the function of Quality Director and General Manager for Fortune 500 companies both domestically and internationally. Mr. Grounds continues to provide learning workshops focusing on Six Sigma, Lean Manufacturing, Corrective and Preventative Actions, and Advanced Product Quality Planning strategies each year to assist ISP Software’s customer base in achieving their goals.

President / SSMBB

Integrated Solution Providers Software, Inc.

P.O. Box 1281

Mount Pleasant, MI 48804

Toll Free: 877.865.7562

Fax: 989.317.0676

E-mail: Admin@ispsoftware-solutions.com

Web Site: http://www.ispsoftware-solutions.com