What Is Process Stability?

What Is Process Stability?

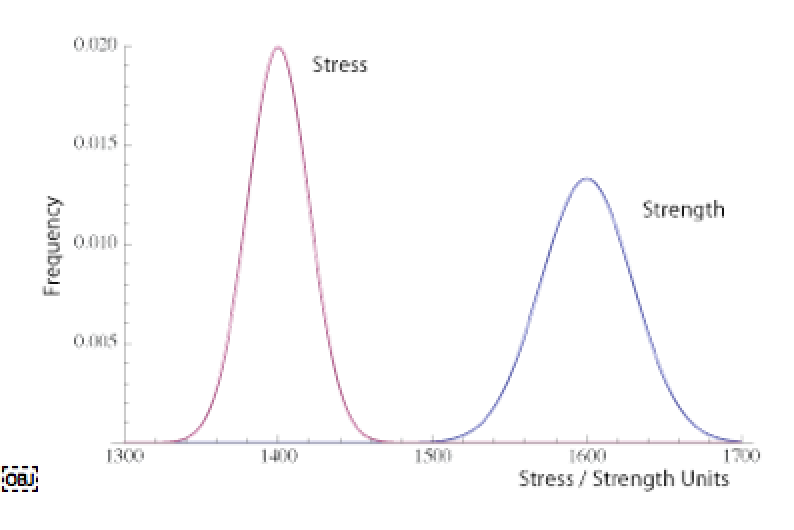

Everything varies. Your vendors provide components with a range of values. Your production process varies, too. Creating, monitoring, and maintaining process stability enhances your product reliability performance.

When I started my professional life as a manufacturing engineer, a senior engineer told me that we take a product design and can only make it worse. He said that, if we could make every unit exactly according to the nominal values of the drawing, every unit would work well. Continue reading